Your product sits in a plain, boring box that fails to grab attention. This generic look hurts your brand and misses a key marketing opportunity, making you invisible on the shelf.

A box sleeve1, also known as a belly band2, is a printed paper or cardstock wrapper that slides over a plain box. It adds branding3, product information4, and a premium feel5 without the cost of a fully custom-printed box. It's a fast, flexible, and affordable packaging upgrade.

A box sleeve1 seems simple. It’s just a piece of paper that wraps around a box, right? I used to think that, too. But after years in this business, I’ve seen how this one simple item can make or break a product's presentation. It’s more than just decoration. It's a tool that can solve many packaging problems6 if you know how to use it correctly. Let's explore what a box sleeve1 really is and how you can use it to make your products stand out.

What Exactly Is a Box Sleeve?

You have a great product inside a standard box, but it looks generic. This lack of branding3 hurts your image. A box sleeve1 is the simple, elegant solution you need.

A box sleeve1 is a paper or cardstock wrapper that slides over an existing box. It’s a printable band that adds custom graphics7, logos, and text to plain packaging. It acts as the primary visual and informational surface for your product.

At its core, a box sleeve1 is a "second skin" for your packaging. I once had a client who called it a "paper ring." They thought it was just a minor decorative touch. We showed them how it could be so much more. A well-designed sleeve transforms a generic container into a branded experience. It has three key aspects that work together.

1. The Physical Form

It is typically a single piece of cardstock that is scored and glued to form a tube. This tube is designed to fit snugly over a box. The fit is the most critical part. Too loose, and it falls off. Too tight, and it rips or is impossible to apply. This is where planning from the start with your supplier is so important.

2. The Branding Canvas

This is where the sleeve shines. It provides 360 degrees of printable space. You can display your logo, brand colors, marketing messages, and high-quality imagery. It tells your brand's story before the customer even opens the box.

3. The Information Layer

Beyond just looking good, the sleeve is a practical tool. It's the perfect place for essential information like nutritional facts8, ingredients, instructions, barcodes, and contact details. This keeps your primary box clean and simple.

Are There Other Names for Box Sleeves?

You hear terms like "belly band2" and "packaging sleeve9" and get confused. This makes searching for suppliers difficult. Knowing the right terms helps you find exactly what you need.

Yes, box sleeve1s are often called belly band2s, packaging sleeve9s, or box wraps. The term "belly band2" is very common, especially for sleeves that only wrap around the middle of a product or a stack of items.

The name often changes depending on the industry or the specific application, which can be confusing. I remember a new client asking for "box belts," and it took us a few minutes to realize they meant sleeves. Understanding the different terms helps you communicate clearly with any supplier. Here’s a quick breakdown of the common names and where you might hear them.

| Term | Common Industry / Use Case | Description |

|---|---|---|

| Box Sleeve | Retail, Food, Cosmetics | The most common and general term. Refers to a sleeve that covers most of a box. |

| Belly Band | Invitations, Apparel, Books | Typically a narrower band that wraps around the "belly" or middle of an item. Often more decorative. |

| Packaging Sleeve | Electronics, General Manufacturing | A broad, technical term used interchangeably with "box sleeve1." |

| Box Wrap | General Retail, Gifting | A less common term, but sometimes used to describe a sleeve that fully wraps a box. |

Ultimately, all these terms describe the same basic concept: a paper or cardstock band that slides over a product or its box. When talking to a supplier, using "box sleeve1" or "belly band2" will almost always get your point across. The most important thing is to have the dimensions of your box ready.

What Are Box Sleeves Actually Used For?

Your packaging needs to do more than just hold a product. It needs to communicate and sell. A plain box fails at this. Sleeves add that vital communication layer.

Box sleeves are used to add branding3, product information4, and promotional messaging to plain packaging. They can also be used to bundle multiple items together or to secure a box lid without tape.

A box sleeve1 is a multi-purpose tool. Its primary job is to make your product look good, but its uses go far beyond that. I've seen clients use them in incredibly creative ways over the years. We can break down their functions into a few main categories.

Branding and Visual Appeal

This is the most obvious use. A sleeve carries your brand's identity. It uses color, typography, and imagery to create an emotional connection with the customer. For a small business, this is a game-changer. It allows you to buy stock boxes in bulk and then create custom, professional-looking packaging for a fraction of the cost of fully printed boxes.

Information Display

A sleeve is prime real estate for information. Think about a box of soap. The sleeve can show the scent, key ingredients, and brand story. For a food product, it holds the nutritional facts8, cooking instructions, and expiration date. This keeps the main box from becoming cluttered with text.

Bundling and Security

Sleeves are also functional. You can use a single sleeve to bundle two or more products together into a gift set. I’ve also seen them used to hold the lid on a two-piece box, removing the need for plastic shrink-wrap or messy wafer seals. It adds a touch of class while serving a practical purpose.

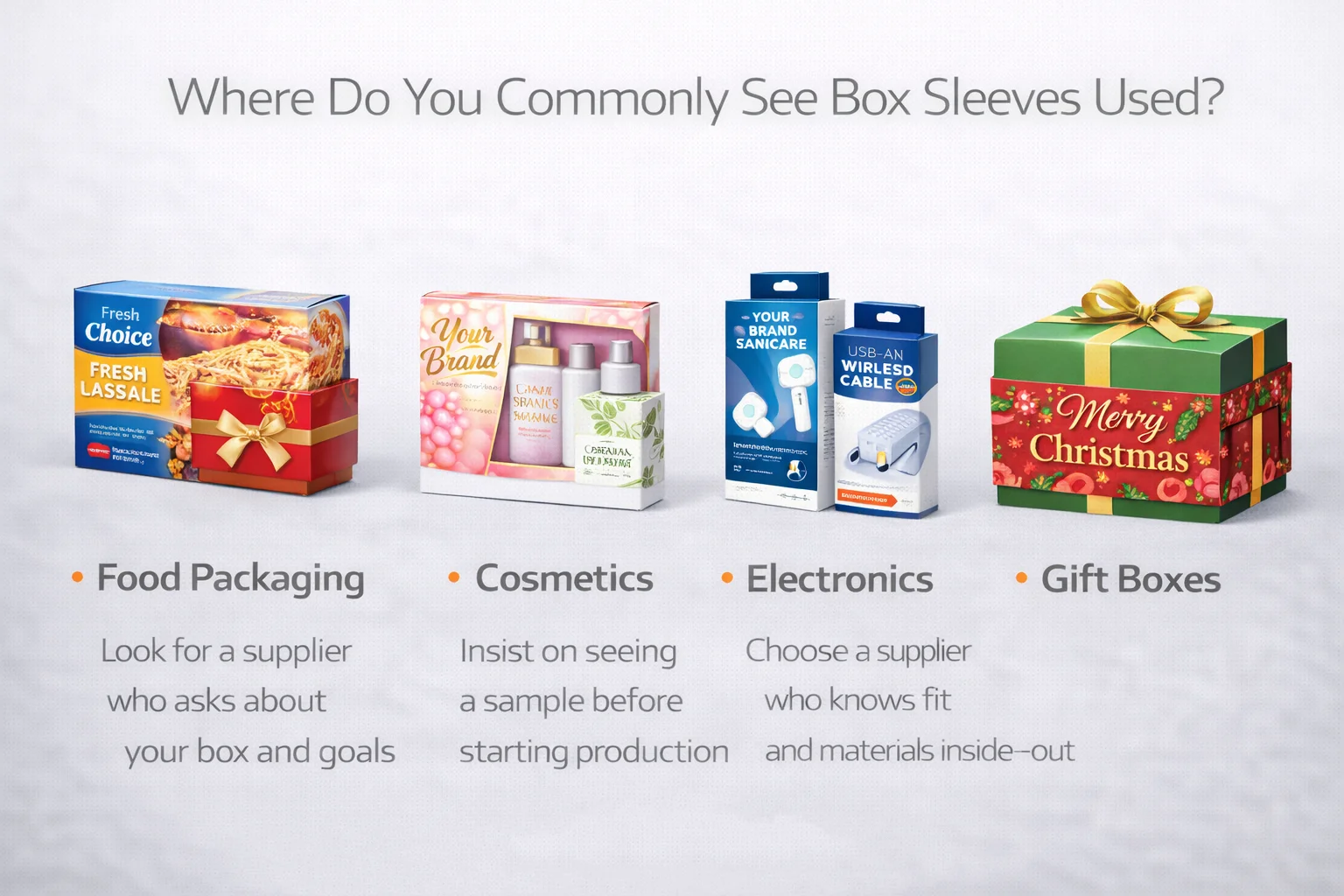

Where Do You Commonly See Box Sleeves Used?

You want to use sleeves but are not sure if they fit your industry. You see them everywhere but can't place them. This makes you hesitate. Let's look at real-world examples.

Box sleeves are very common in food packaging (frozen meals, chocolates), cosmetics (soap, gift sets10), electronics (phone accessories), and retail gift boxes. They provide a premium, customizable finish for many products.

Once you know what a box sleeve1 is, you start seeing them everywhere. They are one of the most versatile packaging solutions across dozens of industries. I worked with a small bakery that used sleeves to turn their standard pastry boxes into beautiful, branded gifts for holidays. They could print small batches for Valentine's Day, then switch to a new design for Easter without being stuck with thousands of outdated boxes. This flexibility11 is key.

Here are some of the most common applications I see every day.

| Industry | Product Example | Why a Sleeve Works Well |

|---|---|---|

| Food & Beverage | Frozen meals, chocolate bars, coffee bags | Allows for easy updates to ingredients or promotions. Provides a premium feel5 for artisanal products. |

| Cosmetics & Personal Care | Soap bars, lotion bottles, gift sets10 | Adds a touch of luxury and provides space for ingredient lists. Great for bundling items into a set. |

| Electronics | Phone cases, chargers, cables | Secures a plain box while adding branding3 and technical specs. Looks more professional than a sticker. |

| Apparel | Rolled t-shirts, socks, underwear | Acts as a belly band2 to keep items neatly bundled and branded without a full box or plastic bag. |

| Gifting | Candles, mugs, corporate gifts | Instantly turns a generic gift box into a custom-branded present for a specific event or client. |

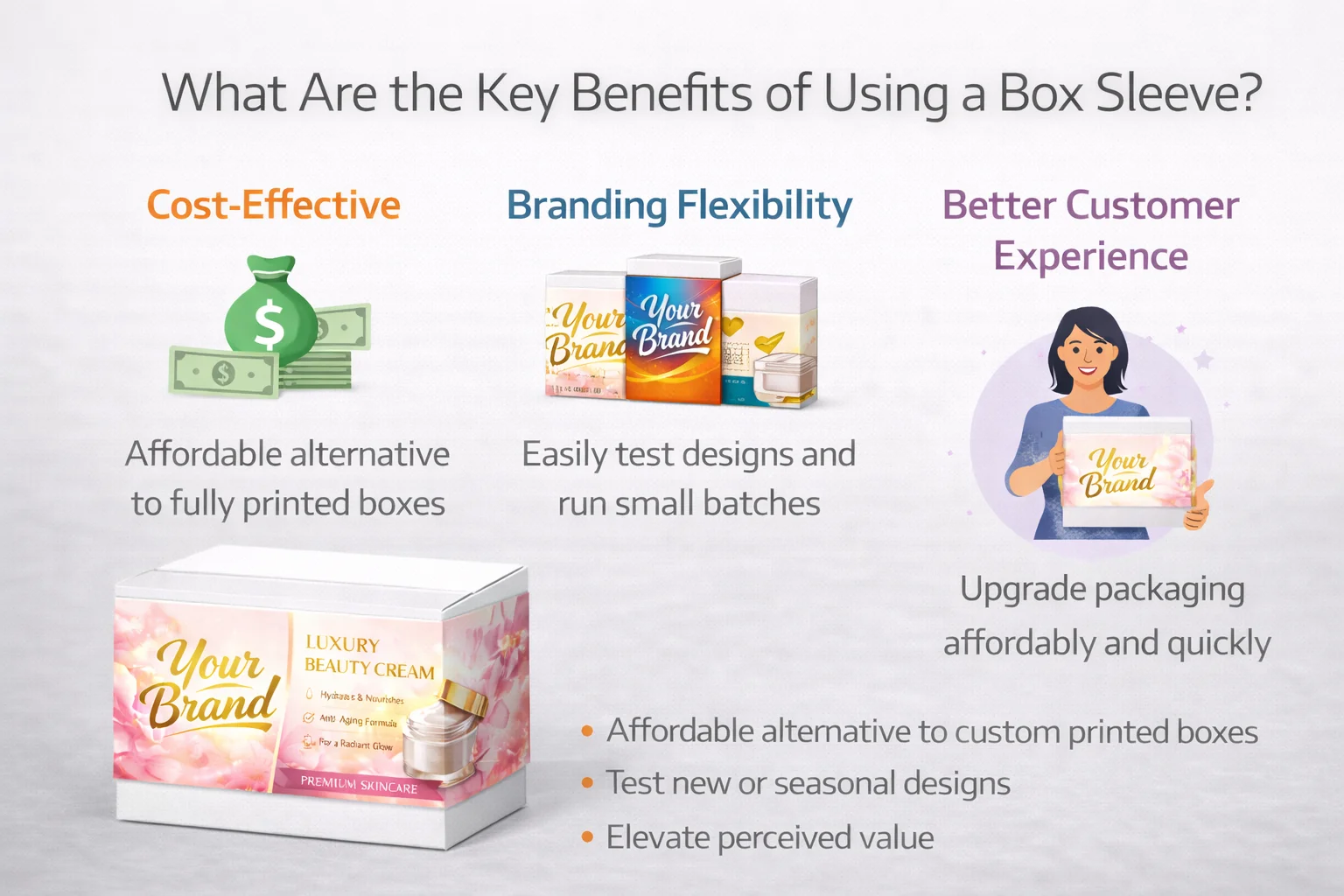

What Are the Key Benefits of Using a Box Sleeve?

Custom printed boxes are expensive, especially for small runs. This high cost can limit your branding3 options. Box sleeves offer a powerful, affordable alternative to elevate your packaging.

The main benefits are cost-effectiveness12, branding3 flexibility11, and an enhanced customer experience13. You can print small batches of sleeves to test designs or for seasonal promotions without committing to a large, expensive box order.

The advantages of using a box sleeve1 are significant, especially for small to medium-sized businesses. It’s not just about saving money; it’s about being smarter and more agile with your packaging strategy. I always get excited when a client realizes how much freedom sleeves can give them.

Cost-Efficiency

This is the biggest draw for most people. Ordering 500 fully custom-printed boxes is very expensive. But ordering 500 plain stock boxes and 500 custom-printed sleeves is much more affordable. You get a professional, branded look for a fraction of the price. This lowers the barrier to entry for high-quality packaging.

Branding Flexibility

This is where sleeves really shine. Do you have a seasonal promotion? Print a special sleeve. Want to test a new brand look? Print a small run of 100 sleeves. You are not locked into a single box design for thousands of units. This flexibility11 allows you to be responsive to market trends without a huge financial risk. It's a key insight from my experience: sleeves make your packaging dynamic.

Sustainability

Many brands are looking for greener options. You can use a simple, unbleached, recycled kraft box and pair it with a sleeve printed on recycled paper with soy-based inks. This combination often has a smaller environmental footprint than a fully printed and coated box. It also communicates your commitment to sustainability14 to your customers.

Should I Choose a Box Sleeve or a Full Printed Box?

You are deciding on your packaging and feel stuck. A full printed box seems premium, but a sleeve is cheaper. Making the wrong choice can be costly and inflexible.

Choose a box sleeve1 for flexibility11, lower costs, and small to medium production runs. Choose a full printed box for a complete, high-end branding3 experience when you have a stable design and large volumes.

This is a question I get almost every week. The answer depends entirely on your business goals, budget, and order volume. Neither one is universally "better" than the other. They are different tools for different jobs. Thinking about it from a manufacturing perspective, the choice comes down to a trade-off between cost, flexibility11, and the total brand experience you want to create. Let's break down the comparison.

| Feature | Box Sleeve with Plain Box | Full Custom Printed Box |

|---|---|---|

| Initial Cost | Low. You pay for printing a flat sheet, not a whole box. | High. Requires custom die-lines and printing on the entire box structure. |

| Minimum Order | Low. Digital printing allows for runs as small as 50-100 units. | High. Offset printing often requires a minimum of 500-1000 units to be cost-effective. |

| Design Flexibility | High. You can easily and cheaply print new sleeve designs for promotions or tests. | Low. Once you print 1000 boxes, you are committed to that design. |

| Lead Time | Short. Sleeves can often be printed and delivered in 1-2 weeks. | Long. Custom boxes can take 4-8 weeks from design approval to delivery. |

| Perceived Value | Good to Excellent. A well-designed sleeve on a quality box looks very premium. | Excellent. Offers a complete, seamless unboxing experience from every angle. |

The best approach I've seen is a phased one. Many brands start with a sleeve to test the market. Once their product is established and sales are consistent, they might invest in a fully printed box for their flagship items while still using sleeves for seasonal specials.

What Materials and Printing Options Are Available for Box Sleeves?

You want a sleeve, but the world of paper and printing is confusing. You don't know your GSM from your CMYK. This can lead to a poor-quality, flimsy result that cheapens your brand.

Common materials15 include kraft paper for an eco-friendly look and coated cardstock for vibrant printing. Printing is usually done with digital methods for short runs or offset methods for large runs.

The material and printing choices you make have a huge impact on the final look and feel of your product. A thin, flimsy sleeve feels cheap, while a thick, textured sleeve communicates quality. I always tell my clients that the material choice impacts the feel as much as the design itself. Here’s a basic guide to the most common options.

Common Materials

The thickness of the paper, called its weight, is measured in GSM (grams per square meter) or Points (pt). For a sleeve, you typically want something between 250-350 GSM (or 10-14 pt) so it's sturdy enough to hold its shape.

- Coated Cardstock (C1S/C2S): Coated on one or two sides. This smooth, shiny surface is perfect for vibrant, full-color photo printing. It’s the most popular choice.

- Uncoated Cardstock: Has a matte, natural texture. It absorbs more ink, giving colors a more subdued look. It's great for elegant, minimalist designs.

- Kraft Paper: This is the brown, recycled-looking paper. It’s perfect for brands wanting an earthy, eco-friendly, or rustic vibe.

Printing and Finishes

- Digital Printing: Perfect for short runs (under 1000). It’s fast and has minimal setup costs, allowing for high-quality, full-color printing.

- Offset Printing: The standard for large runs (1000+). The cost per unit is much lower, and it offers the highest possible quality and color accuracy, including special Pantone colors.

- Finishes: These are special touches you can add after printing. A gloss or matte lamination adds durability and changes the texture. Spot UV adds a shiny, raised effect to specific areas like your logo. Embossing can give your design a 3D texture.

What Are the Common Mistakes to Avoid When Designing Box Sleeves?

You've designed a beautiful sleeve, but when it arrives, it doesn't fit the box. Or the colors look wrong. These mistakes waste time and money, causing major frustration for everyone.

The biggest mistakes are incorrect measurements, ignoring material thickness and box tolerances, and poor design placement. Always, always get a physical prototype to test the fit before a full production run.

This is where my manufacturing insight is most critical. Nearly every problem with a box sleeve comes down to a lack of planning at the design stage. A sleeve design cannot happen in a vacuum. It must be created with the physical box in mind. I’ve had clients send us a file that was designed to the exact dimensions of their box, and we had to explain why it would never slide on.

Mistake 1: Incorrect Measurements and Ignoring Tolerances

A box listed as 4x3x1 inches is rarely exactly that size. There's always a small manufacturing tolerance. More importantly, the sleeve material itself has thickness. You must account for the thickness of the paper on all four sides, plus a little "wiggle room" for it to slide on smoothly. The solution is simple: work with your supplier. Give them a sample of your box, and they will help you create the perfect die-line.

Mistake 2: Poor Graphic Placement

Designers often forget about the corners and the glued flap. It's easy to place a critical piece of information or part of a logo right where the sleeve will be folded or glued. This results in text that is unreadable or a logo that is cut off. The solution: always design on a template (die-line) provided by your printer. It will show you the "safe zones" and the fold lines.

Mistake 3: Wrong Material Choice for the Design

A client once wanted a dark, moody design with subtle black-on-black effects. They also wanted to use uncoated kraft paper to be eco-friendly. The result was a muddy mess because the porous kraft paper absorbed the ink and killed the contrast. The design and the material were fighting each other. The solution: discuss your design goals with your supplier so they can recommend a material that will achieve your vision.

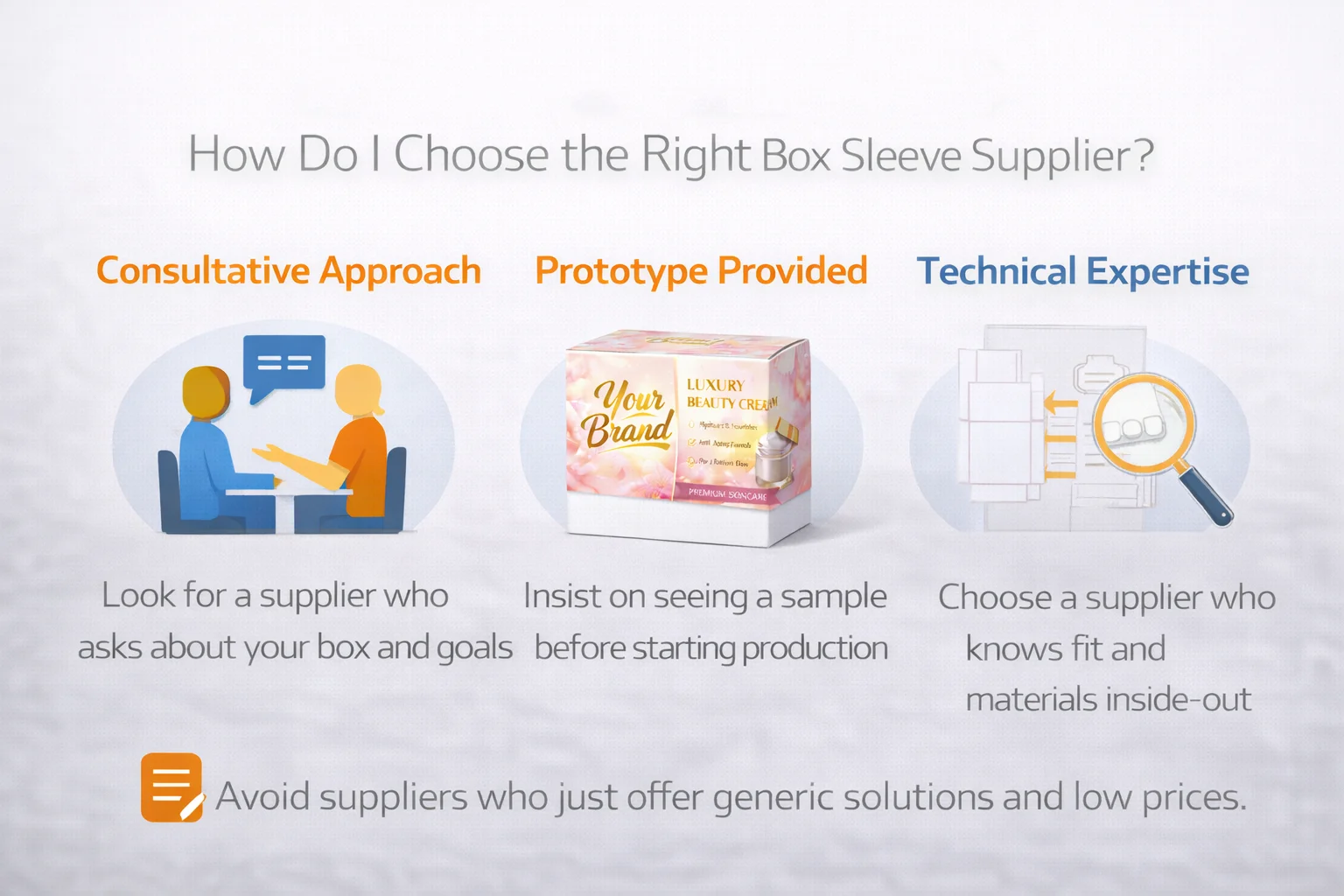

How Do I Choose the Right Box Sleeve Supplier?

You need a supplier, but everyone on the internet promises low prices and high quality. How do you choose a real partner? Choosing the wrong one leads to delays, poor quality, and costly reprints.

Look for a supplier who acts as a consultant, not just an order-taker. A good partner asks detailed questions about your box and goals, insists on providing a prototype, and understands the technical details of fit and materials.

Finding the right supplier is less about finding the lowest price and more about finding the right partner. The cheapest printer is often the one who will just print whatever file you send them, no questions asked. This is a recipe for disaster. A good supplier is part of your team. The best results I've ever produced for clients came from this kind of collaboration.

They Ask the Right Questions

A good supplier won't just ask "How many do you want?" They will ask, "Can you send us a sample of your box?" or "What kind of look are you going for?" or "Is this sleeve being applied by hand or by machine?" These questions show they are thinking about potential problems before they happen.

They Provide Prototypes

A reliable supplier will encourage, or even insist on, creating a physical prototype for you to test. They know that checking the fit, colors, and material in person is the only way to guarantee a successful final run. If a supplier is hesitant to provide a prototype, that is a major red flag.

They Are Experts in Materials

A great partner can look at your design and say, "For that vibrant red, you'll be happier with a coated stock," or "If you want a rustic feel, this kraft paper has a really nice texture." They should be able to send you a sample pack of different materials so you can see and feel them for yourself.

The absolute best outcomes happen when we are involved from the very beginning. When a brand brings us in early, we can help them design the sleeve and box to work together perfectly. This makes the sleeve a flexible, powerful, and cost-efficient tool, not just a last-minute add-on.

Conclusion

Box sleeves are a cost-effective, flexible tool. When planned correctly with your box and your supplier, they powerfully elevate your brand's packaging and the entire customer experience.

Explore how a box sleeve can transform your product's presentation and branding. ↩

Learn about belly bands and how they can add a decorative touch to your products. ↩

Understand the importance of branding in packaging and how it influences consumer perception. ↩

Understand the essential product information that should be communicated to consumers. ↩

Discover the elements that create a premium feel in packaging and enhance customer experience. ↩

Explore how box sleeves can address various packaging challenges effectively. ↩

Find out how custom graphics can enhance your product's appeal and marketability. ↩

Explore best practices for displaying nutritional facts to comply with regulations and inform consumers. ↩

Discover the versatility of packaging sleeves and their applications across industries. ↩

Discover creative ways to use packaging sleeves for bundling products into attractive gift sets. ↩

Explore the benefits of flexible packaging options for businesses and consumers. ↩

Understand how box sleeves can save you money while maintaining quality packaging. ↩

Understand the connection between packaging design and overall customer satisfaction. ↩

Discover eco-friendly packaging options and their benefits for your brand and the environment. ↩

Explore the different materials available for box sleeves and their impact on quality. ↩