Struggling to pick the perfect box for your serum? The wrong choice can damage your product and your brand's reputation. This guide will help you make the right decision.

The best materials for serum packaging1 are sturdy paperboards2 like SBS or Kraft for protection and a premium feel. Popular box styles include tuck-end boxes3 for retail and mailer boxes4 for e-commerce, often with custom inserts5 to hold the bottle securely. It’s all about balancing protection, branding, and cost.

Choosing the right packaging is one of the most important decisions you'll make for your cosmetic brand. It's the first thing your customer touches and sees. Let's dive into the details to make sure you get it right.

Why Does Serum Packaging Matter So Much?

Is your packaging just a box, or is it a crucial part of your brand? It’s easy to overlook, but this choice has a huge impact on your business's success.

Your packaging is your silent salesperson. It communicates your brand's value before the customer even tries the serum. Good packaging protects the product, tells your brand story, and creates a memorable experience that keeps customers coming back for more. It's a critical investment, not just a cost.

I learned this the hard way early on. We launched a fantastic serum, but we used cheap, flimsy boxes to save money. We got emails about damaged bottles and saw comments that our product looked low-quality. It was a painful lesson. Your box isn't just a container; it's the first promise you make to your customer. It needs to show that you care about quality from the inside out. Great packaging builds trust and makes the customer feel special. It sets the stage for the amazing product inside.

Brand Perception

The look and feel of your box create an instant impression. A thick, beautifully printed box suggests a luxury product worth a higher price. A simple, recycled Kraft box communicates an eco-conscious, natural brand identity. This perception is formed in seconds.

Product Safety

Serums often come in glass bottles and contain sensitive active ingredients. The packaging's main job is to protect the product from breaking during shipping. It also needs to shield the formula from light, which can degrade its effectiveness.

| Aspect | Good Packaging | Bad Packaging |

|---|---|---|

| First Impression | Premium, trustworthy | Cheap, unreliable |

| Product Safety | Secure, protected | Damaged, broken |

| Brand Story | Clear, compelling | Confusing, non-existent |

| Unboxing | Exciting, memorable | Frustrating, forgettable |

What Are The Most Common Materials for Serum Boxes?

Are you wondering what material will best protect your serum and reflect your brand? The material you choose affects everything from durability to the customer's perception of your product's quality.

The most common materials are paper-based boards. Cardboard (SBS) is popular for its smooth, bright white surface, which is great for printing vibrant colors. Kraft paper6 offers a natural, earthy look. For luxury brands, rigid board7 provides a heavy, high-end feel that screams quality.

Choosing the right material is a balancing act. You need something strong enough to survive shipping but also beautiful enough to stand out on a shelf. I once worked with a brand that wanted a super-luxe feel. We chose a thick rigid board7, and the weight of the box alone made the product feel incredibly valuable. For another client focused on sustainability, we used 100% post-consumer recycled Kraft paper6. Both choices were right for their specific brands. Think about your brand identity first, then select the material that tells that story best.

Everyday Choices

For most brands, coated paperboard, often called SBS (Solid Bleached Sulfate), is the go-to. It’s cost-effective, durable, and provides a fantastic surface for printing. Uncoated Kraft paper6 is another great option, especially if you have a natural or organic brand. It has a rustic charm and is often seen as more eco-friendly.

Premium & Shipping Options

For high-end serums, a rigid box is the ultimate choice. It's made from thick chipboard wrapped in paper, creating a sturdy, gift-like container. For shipping directly to customers, corrugated cardboard8 is essential. It has that wavy layer in the middle which provides excellent cushioning against bumps and drops.

| Material | Best For | Print Quality | Durability | Cost |

|---|---|---|---|---|

| Cardboard (SBS) | Retail shelves, vibrant designs | Excellent | Good | $$ |

| Kraft Paper | Eco-friendly, natural brands | Good (Rustic) | Good | $$ |

| Rigid Board | Luxury & gift sets | Excellent | Excellent | $$$$ |

| Corrugated | E-commerce shipping | Fair to Good | Excellent | $ |

What Are The Most Popular Box Styles?

With so many box designs out there, which style is the right fit for your serum? The structure of the box is just as important as the material it's made from.

The most popular styles are tuck-end boxes3 for retail and mailer boxes4 for e-commerce. Tuck-end boxes are the classic cosmetic boxes you see in stores. Mailer boxes are sturdier, self-locking boxes designed to be shipped without an outer container, perfect for subscription services.

The style you choose should be practical for your sales channel. If you sell primarily in physical stores, a straight tuck-end box with a hanging tab might be perfect. It looks clean and hangs well on displays. If you're an online-only brand, a roll-end tuck-front mailer box offers better protection and a more exciting unboxing experience9. I always advise clients to think about the customer's journey. Will they see it on a shelf or on their doorstep? The answer will guide you to the perfect box style.

Retail-Ready Styles

Tuck-end boxes are a staple. A Straight Tuck End (STE) has both top and bottom flaps folding to the back, creating a clean front panel. A Reverse Tuck End (RTE) has flaps that fold in opposite directions, which can be slightly more economical to produce. For luxury products, a two-piece rigid box (a base and a lid) offers a premium, gift-like feel.

E-commerce Essentials

The Mailer Box (also known as a roll-end tuck-front) is the king of e-commerce. It's made from a single piece of corrugated cardboard8 that folds together to create a strong, secure package. It provides excellent protection during transit and a satisfying "reveal" when opened by the customer.

| Box Style | Primary Use | Assembly | Security | Unboxing Feel |

|---|---|---|---|---|

| Tuck-End Box | Retail | Fast | Good | Standard |

| Mailer Box | E-commerce | Moderate | Excellent | Premium |

| Two-Piece Box | Luxury / Gift | None (Pre-made) | Excellent | Very Premium |

How Do You Choose The Right Box For Your Serum Bottle?

Have you thought about how your specific bottle will fit inside the box? A poor fit can lead to rattling, breakage, and a disappointing customer experience. It's a small detail with big consequences.

The key is a snug fit. Your box should be designed around your bottle's exact dimensions, with minimal empty space. For extra security, especially with glass bottles, use a custom-designed insert made from paperboard or foam to hold the bottle perfectly in place.

I remember a client who came to me after a disastrous product launch. They used a standard-sized box for their custom-shaped bottle. Nearly 20% of their first shipment was damaged. We redesigned the packaging with a simple, die-cut paperboard insert that hugged the bottle. It added very little to the cost but completely solved the breakage problem. Don't just put your bottle in a box; design the box for the bottle. This simple shift in thinking protects your product and your profits.

The Perfect Fit

Measure your bottle carefully—height, width, and depth. Provide these exact measurements to your packaging supplier. The goal is to immobilize the bottle. A box that is too big allows the product to slide around and break. A box that is too small can be difficult to open or can even damage the bottle's pump or dropper.

Inside Matters: Inserts

Inserts are the best way to guarantee a secure fit. They are custom-made pieces that sit inside the box and hold the product.

- Paperboard Inserts: Cost-effective, recyclable, and can be custom-cut to any shape.

- Molded Pulp Inserts: Eco-friendly and offer great cushioning.

- Foam Inserts (EVA): Provides a high-end, premium feel and maximum protection, but is less sustainable.

| Bottle Type | Recommended Box Style | Recommended Insert |

|---|---|---|

| Glass Dropper Bottle | Tuck-End or Mailer | Paperboard or Molded Pulp |

| Airless Pump Bottle | Tuck-End or Mailer | Paperboard |

| Luxury Glass Bottle | Two-Piece Rigid Box | Foam (EVA) or Paperboard |

What Printing & Finishing Options Will Make Your Box Stand Out?

Are you wondering how to make your packaging look truly unique and professional? The printing and finishing touches are what elevate a plain box into a stunning piece of branding.

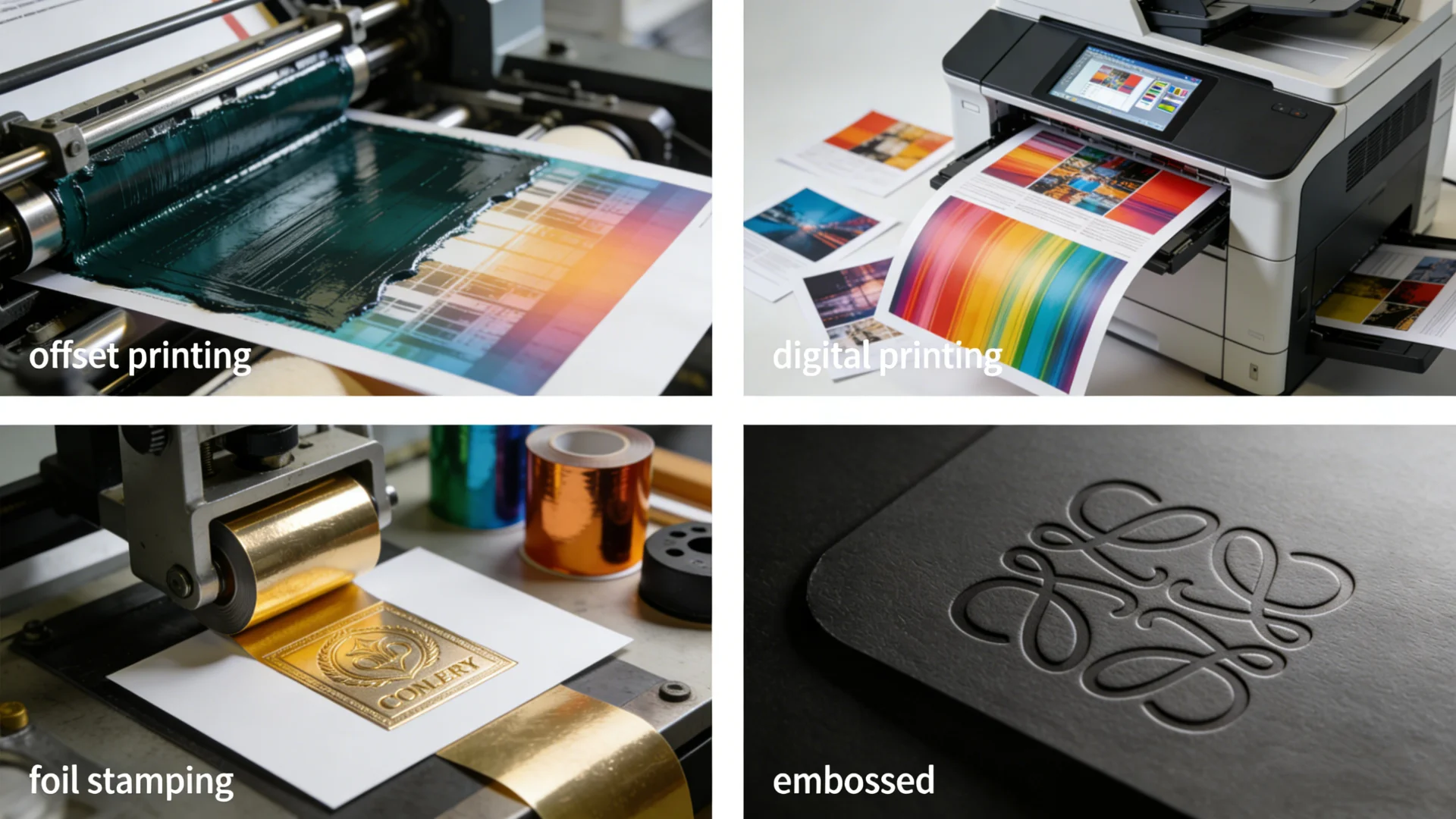

For a professional look, choose offset printing10 for large runs and digital printing11 for smaller quantities. Then, add special finishes like foil stamping12 for a metallic shine, embossing13 to create a raised texture, or a spot UV coating to make your logo pop with gloss.

These little details make a huge difference. I worked with a startup that had a beautiful logo, but it looked flat on their box. We added a simple gold foil stamp to the logo and an embossed texture to the brand name. The box instantly looked ten times more luxurious. Customers started posting photos of the packaging on social media. These finishes aren't just decorative; they are powerful tools that add perceived value and make your brand more memorable. Don't be afraid to experiment with one or two to see the impact.

Making it Pop with Printing

- Offset Printing: This is the standard for high-quality, large-volume printing. It produces crisp, consistent colors. Best for orders over 1,000 units.

- Digital Printing: Perfect for smaller runs or when you need variable data. It has a faster setup time and is more cost-effective for low quantities.

A Touch of Luxury with Finishes

Finishes are applied after printing to add texture and visual appeal.

- Foil Stamping: Applying a thin layer of metallic or colored foil to the box.

- Embossing / Debossing: Pressing a die into the paper to create a raised (emboss) or indented (deboss) design.

- Spot UV: Applying a high-gloss coating to specific areas (like a logo) to make them stand out against a matte background.

| Finishing Option | Visual Impact | Tactile Feel | Added Cost |

|---|---|---|---|

| Foil Stamping | High (Shiny, metallic) | Smooth | $$$ |

| Embossing | Medium (Subtle 3D) | High (Raised texture) | $$ |

| Spot UV | High (Glossy contrast) | Medium (Smooth feel) | $$ |

| Matte/Gloss Lamination | Medium (Overall finish) | Smooth | $ |

How Can You Make Your Packaging Sustainable & Eco-Friendly?

Is sustainability important to your brand and your customers? Choosing eco-friendly packaging is no longer a niche trend; it's a powerful way to connect with modern consumers and build a responsible brand.

Focus on the three R's: Reduce, Reuse, and Recycle. Use materials like FSC-certified paper14 or recycled content. Print with soy-based inks15. Design your box to be easily recyclable by avoiding mixed materials like plastic windows or magnets. Simplicity is often the most sustainable choice.

Being eco-friendly is a huge competitive advantage. I advise my clients to not only use sustainable materials but to talk about it. Add a small FSC logo or a note like "This box is 100% recyclable" to your packaging. It shows transparency and reinforces your brand's values. Customers appreciate this. They feel good about their purchase, which builds loyalty. It’s a win for your brand and a win for the planet. Making a conscious choice here can have a surprisingly large impact on how your brand is perceived.

More Than Just Brown Paper

While Kraft paper6 is a great visual cue for "natural," sustainability goes deeper.

- FSC-Certified Paper: This ensures the paper comes from responsibly managed forests.

- Recycled Content: Look for paperboard with a high percentage of post-consumer waste (PCW).

- Soy-Based Inks: These are more environmentally friendly than traditional petroleum-based inks.

Communicating Your Commitment

Your sustainable efforts are a selling point. Make them visible. A simple logo or a short sentence on the bottom of the box can communicate your commitment effectively. This helps justify a premium price and attracts customers who share your values. Don't hide your good work; make it part of your brand story.

| Sustainable Feature | Environmental Benefit | Consumer Perception |

|---|---|---|

| FSC-Certified Paper | Promotes responsible forestry | Ethical, trustworthy |

| High Recycled Content | Reduces landfill waste | Eco-conscious, responsible |

| Soy-Based Inks | Lower air pollution | Thoughtful, modern |

| Easily Recyclable Design | Reduces processing energy | Practical, user-friendly |

How Can You Manage Customization and Budget?

Are you worried that custom packaging is too expensive for your brand? It doesn't have to be. With smart planning, you can create beautiful custom boxes without breaking the bank.

Start with a standard box size to avoid high setup fees for a custom die-line. Focus your budget on one or two high-impact finishes16 rather than trying to do everything. Most importantly, increase your order quantity, as the price per box drops significantly with larger runs.

I always tell new brands to start smart. For your first run, maybe you use a simple printed box. As you grow and can place larger orders, you can add a foil stamp. Then later, an embossed pattern. Packaging can evolve with your brand. The key is to find a supplier who can grow with you. A good partner will help you find the most cost-effective way to achieve a premium look at every stage of your business, from a few hundred boxes to tens of thousands.

Smart Spending

- Die-line: This is the template for cutting your box. Using a supplier's existing die-line can save you hundreds of dollars in setup fees.

- Order Quantity (MOQ): The Minimum Order Quantity. The higher your order, the lower your per-unit cost. The initial setup is where most of the cost is, so spreading that over more units is key.

- Finishes: Choose one "wow" factor. A single, well-placed foil stamp on a simple box often looks more elegant and expensive than a box cluttered with too many finishes.

Planning for Growth

Don't over-invest on your very first order. Test the market with a smaller, more affordable run. Once you have proof of concept and steady sales, you can invest in a larger order with more complex features. This approach minimizes risk and allows your packaging to improve as your revenue grows.

| Cost Factor | How to Save Money | Impact on Quality |

|---|---|---|

| Die-line Creation | Use a standard size from your supplier | None |

| Printing | Order a higher quantity | None (improves with offset) |

| Materials | Choose SBS or Kraft over rigid board | Depends on brand goal |

| Finishes | Select only one or two impactful ones | Focuses the design |

How Do You Choose a Reliable Supplier?

How can you be sure you're picking the right company to produce your packaging? Your supplier is a long-term partner, and choosing the right one is critical for a stress-free process.

Look for a supplier with experience in the cosmetics industry. Check their portfolio and ask for physical samples of their work. A reliable partner will communicate clearly, understand your brand vision, and provide a detailed quote without hidden fees. Don't just choose based on the lowest price.

My best advice is to always, always get a sample. I once had a client who skipped this step to save time. The colors on their final 5,000 boxes came out completely wrong, and it was a costly, time-consuming nightmare to fix. A physical prototype lets you see and feel the box exactly as your customer will. It allows you to check the colors, test the fit of your bottle, and approve the quality of the material. A good supplier will insist on this step. It's a sign that they care about getting it right.

Vetting Your Partner

Before committing, do your homework. Read reviews and ask for references. Do they have a gallery of past work you can look at? A good supplier will be proud to show you examples of boxes they've made for brands similar to yours. This shows they understand the quality standards and specific needs of the beauty industry, like precise color matching and flawless finishing.

The Importance of Samples

There are a few types of samples to ask for:

- Stock Samples: Examples of their previous work so you can judge their general quality.

- Digital Proof: A flat PDF layout showing your design on the die-line.

- Physical Prototype: A fully assembled sample of your box with your design. This is the most important one. It's your last chance to catch any errors before full production.

| Supplier Checklist | What to Look For |

|---|---|

| Portfolio | Do they have experience with cosmetic brands? |

| Communication | Are they responsive, clear, and helpful? |

| Sample Quality | Do their samples feel high-quality and well-made? |

| MOQ & Pricing | Is their minimum order quantity reasonable? Is their pricing transparent? |

| Capabilities | Can they produce the materials and finishes you want? |

Conclusion

Choosing the right material, style, and supplier is key to creating serum packaging that protects your product, builds your brand, and delights your customers. Start with these fundamentals.

Explore this resource to understand how effective serum packaging can enhance your brand's image and product safety. ↩

Learn why sturdy paperboards like SBS and Kraft are essential for protecting your products and enhancing their appeal. ↩

Discover how tuck-end boxes can improve your retail presentation and customer experience. ↩

Find out how mailer boxes can provide better protection and enhance the unboxing experience for online customers. ↩

Understand the importance of custom inserts in ensuring product safety and enhancing customer satisfaction. ↩

Discover why Kraft paper is a popular choice for eco-friendly and natural branding. ↩

Find out how rigid board packaging can enhance the luxury feel of your products. ↩

Learn how corrugated cardboard provides excellent protection for products during transit. ↩

Explore how thoughtful packaging design can create memorable unboxing experiences for customers. ↩

Explore the advantages of offset printing for achieving high-quality packaging designs. ↩

Understand the benefits of digital printing for smaller runs and customized packaging. ↩

Discover how foil stamping can add a luxurious touch to your packaging design. ↩

Learn how embossing can create a tactile experience that enhances your brand's image. ↩

Understand the significance of using FSC-certified paper in promoting responsible forestry. ↩

Learn how soy-based inks can reduce environmental impact and enhance your brand's sustainability. ↩

Learn about various high-impact finishes that can elevate your packaging design. ↩