Your current packaging might be hurting the planet and your brand. Customers are noticing and demanding change. This guide provides the clear answers you need to make the switch.

Sustainable packaging uses materials and practices that reduce environmental impact. It considers the entire life cycle, from sourcing and manufacturing to disposal, aiming for a circular system of reuse, recycling, or composting instead of a linear path to the landfill. It's about protecting both your product and the planet.

I’ve worked with many businesses over the years. I've found the biggest thing holding them back from sustainable packaging isn't money. It's confusion. They don't know where to start or what materials to choose. This guide is designed to fix that. It will give you a clear path forward, helping you make confident decisions for your business and for the environment. Let's get started.

What Is Sustainable Packaging, Really?

The term "sustainable" can feel vague and confusing. This uncertainty can lead to mistakes or even accusations of greenwashing. Let's establish a clear, simple definition for your business.

Sustainable packaging is designed to be as safe and effective as possible for both people and the environment throughout its entire life. It is sourced responsibly, manufactured cleanly, transported efficiently, and recovered effectively after use.

To truly understand sustainable packaging, we need to look at its full journey. It's not just about the final box. It's about a series of conscious choices made at every single stage. I break it down into four core areas for my clients. This helps them see the bigger picture and evaluate their options more effectively. A package is only truly sustainable if it performs well across all of these stages, from the forest or farm all the way to its next life.

The Four Pillars of Sustainable Packaging

| Pillar | Description | Key Questions to Ask |

|---|---|---|

| Responsible Sourcing | Materials are renewable or recycled. They are gathered in a way that does not harm ecosystems. | Is this material made from recycled content? Is it from a responsibly managed forest (like FSC-certified)? |

| Clean Manufacturing | The production process minimizes waste, pollution, and energy use. It is safe for workers. | Does the supplier use renewable energy? How do they manage water and waste in their factory? |

| Efficient Use | The packaging protects the product without being excessive. It is lightweight and optimized for shipping. | Can we make this package smaller or lighter? Does it use only the necessary amount of material? |

| Effective Recovery | The packaging can be easily reused, recycled, or composted by the end consumer. | Is this material widely recyclable in my customers' areas? Is it clearly labeled for proper disposal? |

Why Should Your Business Care About Sustainable Packaging in 2026?

Ignoring sustainability might seem like the easy path. But in today's market, it's a costly mistake that affects sales, compliance, and your brand's future. Let's explore the powerful reasons to act.

In 2026, sustainable packaging is non-negotiable. It addresses the global waste crisis, meets strong consumer demand, prepares you for new regulations, and gives your brand a critical competitive edge. It's a business necessity, not just an ethical choice.

The world has changed. What was once a niche interest for "green" consumers is now a mainstream expectation. I see this every day. Brands that lead with sustainability are winning customer loyalty. Those who lag behind are being called out online and are losing market share. This isn't just about feeling good; it's about smart business strategy. The forces driving this change are powerful and are only getting stronger. Let's break them down.

Global Waste Crisis in 2026

Our planet is struggling with waste. Landfills are overflowing, and oceans are filled with plastic. This problem is visible and urgent. Consumers and governments are no longer willing to accept packaging that adds to this crisis. Businesses are now seen as key players in finding a solution, not just contributing to the problem.

Consumer Expectations

Today's shoppers are informed and selective. They actively look for brands that share their values. A 2026 study shows over 70% of consumers are willing to pay more for products with sustainable packaging. They check labels, research materials, and choose brands that demonstrate a real commitment to the environment. Your packaging is often their first impression of your brand's values.

Regulatory Pressure

Governments worldwide are taking action. We're seeing more laws that ban certain single-use plastics, mandate recycled content, and create producer responsibility schemes. These regulations make companies financially responsible for the packaging they create. Getting ahead of these laws saves you from future fines and redesign costs.

Brand Competitiveness

Sustainable packaging makes your brand stand out. It tells a positive story and builds an emotional connection with customers. In a crowded market, it's a powerful differentiator that can boost your reputation, attract top talent, and open doors to new retail partners who have their own sustainability goals.

What Are the Main Types of Sustainable Packaging Materials?

The number of "eco-friendly" material options can be overwhelming. Choosing the wrong one is a mistake that can cost you money and customer trust. Here is a simple breakdown of your choices.

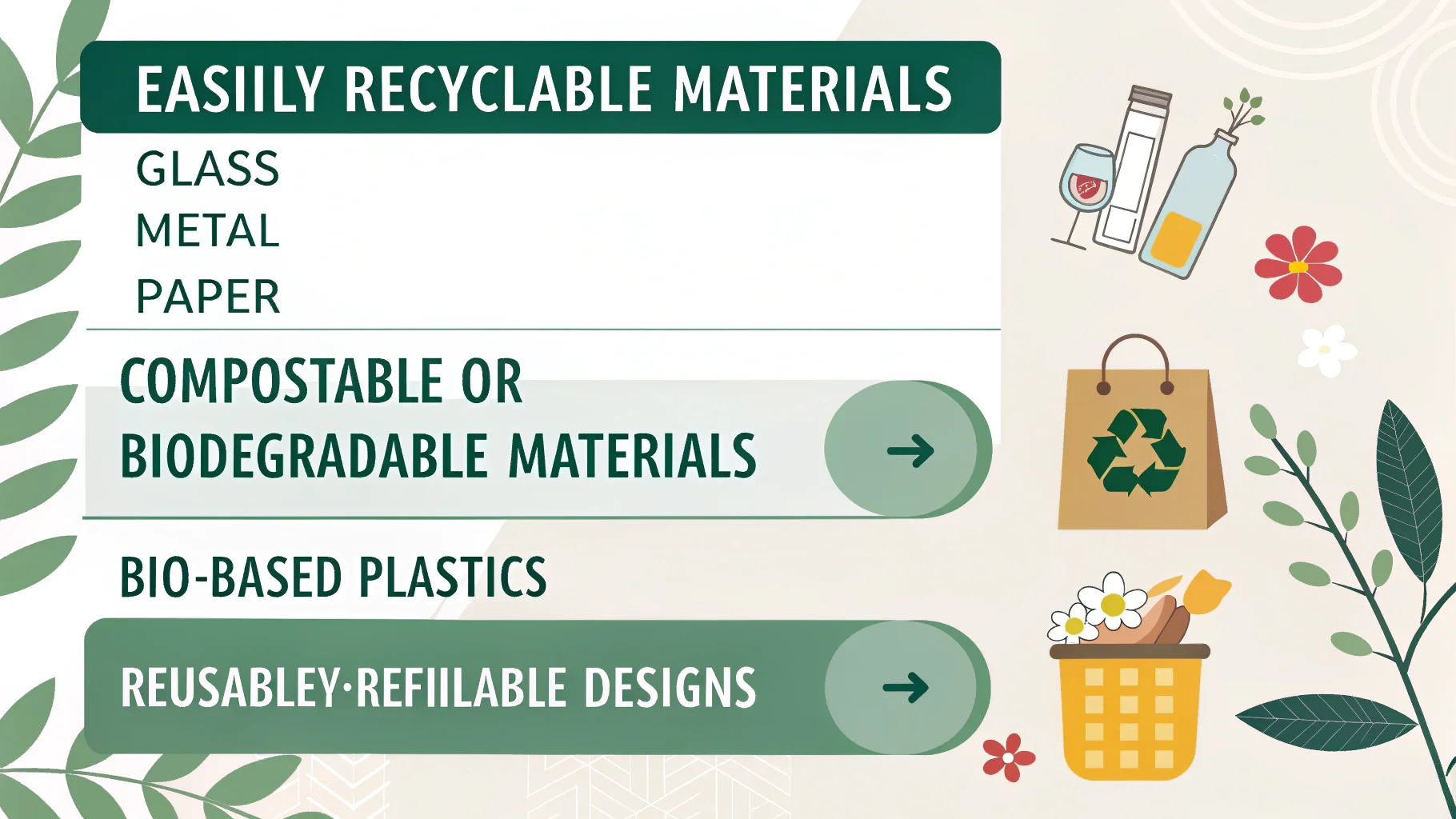

The main types of sustainable materials include those that are easily recyclable (glass, metal, paper), compostable or biodegradable, made from bio-based plastics, or designed for reuse and refilling. Each has its own best-use case and end-of-life path.

Choosing the right material is about matching it to your product, your customer, and your brand. There is no single "best" material for everything. For example, a glass jar is perfect for a luxury cosmetic cream but terrible for shipping a t-shirt. I always advise clients to first understand the fundamental categories. This helps narrow down the options and makes the selection process much less intimidating. Let's look at the most common types you will encounter.

Recyclable Materials

These are the most familiar. Materials like paper, cardboard, glass, and aluminum have well-established recycling systems. The key is using materials that are actually recycled in the areas where your customers live. Using mono-materials (packages made from a single material) greatly increases the chance of successful recycling.

Biodegradable vs. Compostable

These terms are often confused, but they are very different.

| Term | Definition | End-of-Life Environment |

|---|---|---|

| Biodegradable | Can be broken down by microbes over time. However, this term is unregulated and can be misleading. | Can break down in nature, but the timeframe and resulting elements (like microplastics) are not guaranteed. |

| Compostable | Breaks down into natural, non-toxic components in a specific timeframe under controlled conditions. | Requires an industrial composting facility (for most certified materials) to break down properly. |

Other Key Materials

- Bio-Based Plastics: These are plastics made from renewable sources like cornstarch or sugarcane (e.g., PLA). They are not always biodegradable or recyclable. Their main benefit is reducing reliance on fossil fuels.

- Paper & Cardboard: When sourced from FSC or PEFC-certified forests, these are excellent, highly-recyclable options. They are versatile for boxes, mailers, and wraps.

- Reusable & Refillable Packaging: This is the gold standard of sustainability. It creates a circular system where the package is used many times, eliminating waste entirely. It requires a system for customers to return or refill containers.

- Plant Fiber Materials: These include materials made from bamboo, mushroom mycelium, or agricultural waste. They are often compostable and can be molded into protective shapes, replacing plastic foams.

How Does Sustainable Packaging Compare to Traditional Plastic?

Traditional plastic is cheap, lightweight, and familiar. But its hidden costs to the environment and your brand reputation are growing every year. Let's do a head-to-head comparison.

Compared to traditional plastic, sustainable options often have a lower environmental impact across their life cycle. While some may have a higher initial cost, they can offer long-term savings through reduced waste fees and enhanced brand value.

When I talk to business owners, the conversation often turns to plastic. It's a material we all know. But its story doesn't end when the customer opens the product. Its real cost is measured over centuries in our oceans and landfills. Sustainable alternatives are designed with the end in mind. They aim to be part of a cycle, not a one-way trip to the trash. Let's break down the key differences.

Environmental Impact

- Traditional Plastic: Most are derived from fossil fuels, a non-renewable resource. Their production is energy-intensive. Many plastics, especially flexible films and mixed materials, are not recyclable and persist in the environment for hundreds of years.

- Sustainable Packaging: Materials are often from renewable sources (plants, trees) or recycled content. This reduces the need for virgin resources. Their end-of-life is designed to be beneficial (compost) or circular (recycling, reuse).

Cost Comparison in 2026

- Traditional Plastic: Virgin plastic often has a low upfront cost. However, with increasing regulations and Extended Producer Responsibility (EPR) fees, the total cost of using plastic is rising.

- Sustainable Packaging: Some materials, like custom-molded pulp, can have higher initial tooling costs. However, materials like recycled cardboard can be very cost-competitive. The real ROI comes from increased customer loyalty and avoiding future non-compliance fees.

Life-Cycle Analysis

A life-cycle analysis (LCA) is a scientific way to measure the total environmental impact of a product, from creation to disposal.

| Stage | Traditional Plastic | Sustainable Alternative (e.g., Recycled Cardboard) |

|---|---|---|

| Sourcing | Fossil fuel extraction | Recycled paper pulp collection |

| Manufacturing | High energy, potential emissions | Lower energy, water recycling often used |

| Transport | Lightweight, efficient | Can be slightly heavier, but often ships flat |

| Disposal | Landfill, ocean pollution | High recycling rates, becomes new products |

What Is the Life Cycle of Sustainable Packaging?

You see the final box, but you don't see the full journey. Understanding this process is key to choosing materials that are genuinely sustainable, not just green on the surface.

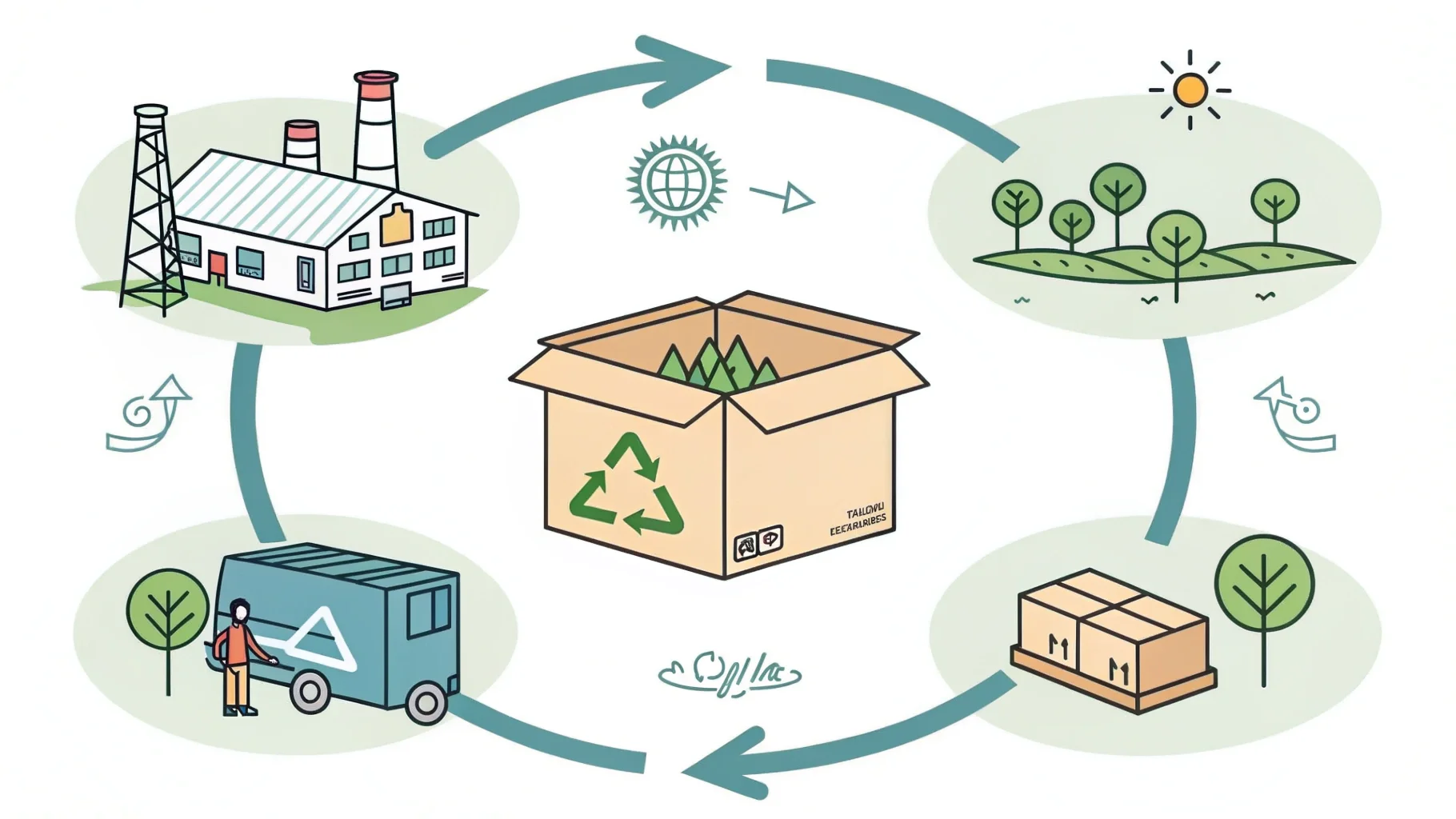

The life cycle of sustainable packaging follows a circular path: it starts with responsibly sourced materials, uses clean manufacturing, serves its purpose effectively, and is then recovered to be made into something new through recycling, composting, or reuse.

Unlike the traditional "take-make-waste" model, a sustainable approach is all about creating a closed loop. I encourage my clients to think like a system designer. Every choice you make at the beginning of the life cycle has a huge impact on what's possible at the end. A package that mixes paper and plastic might look nice, but if it can't be easily separated, it's destined for the landfill. Simplicity is often the key to a truly circular and sustainable outcome.

Stage 1: Sourcing and Manufacturing

This is where it all begins. Sustainable packaging starts with better ingredients. This means choosing materials that are either renewable, like wood from a certified forest, or made from recycled content, like rPET plastic. The manufacturing process itself should also be clean. This involves using renewable energy, minimizing water usage, and reducing waste and emissions. A good supplier will be transparent about their factory's environmental performance and certifications.

Stage 2: Use and Performance

A package's primary job is to protect the product. If it fails, the product is wasted, which is the worst possible environmental outcome. Sustainable packaging must be "fit for purpose." It needs to be durable enough for shipping and storage. The design should also be efficient, a practice known as "right-sizing." This means using the least amount of material necessary to do the job effectively, which reduces waste and shipping costs.

Stage 3: Disposal and Recovery

This is the most critical stage. What happens after the customer is done with the packaging? A sustainable package is designed for a positive end-of-life.

- Reuse: The customer can use the container for another purpose.

- Recycling: The material can be easily collected, sorted, and reprocessed to make new products.

- Composting: The material breaks down in a compost environment to become nutrient-rich soil. Clear instructions for the customer are essential here. A compostable package thrown in the recycling bin contaminates the recycling stream.

How Do You Choose the Right Sustainable Packaging for Your Business?

You are ready to make a change, but you don't know where to begin. Making the wrong choice can lead to wasted time, money, and even damaged products. Let's create a clear decision-making framework.

To choose the right sustainable packaging, you must analyze your product's needs, your budget, your supply chain's reliability, and your customer's access to recycling or composting. A balanced approach that considers all these factors leads to the best solution.

From my experience, the most successful transitions happen when a business creates a scorecard for its packaging options. It's not about finding a "perfect" material, but the "best fit" for your unique situation. One of the most overlooked factors is the supply chain. A fantastic new compostable material is useless if you can't get it consistently and at a stable price. A reliable supplier is just as important as a sustainable material.

Key Decision Factors

Start by asking these four critical questions:

- What does my product need? Does it need protection from moisture? Is it fragile? Does it need a food-safe barrier? Your product's physical requirements will immediately rule out some materials.

- What is my budget? Be honest about your cost constraints. This includes the price per unit, shipping costs, and any new equipment you might need. Look at the total cost, not just the material price.

- What can my customer handle? Does your target customer have access to curbside recycling for paper? Do they live in a city with an industrial composting program? Packaging is only effective if it can be disposed of correctly.

- What does my brand stand for? Does your packaging need to look and feel luxurious? Or is a more natural, kraft-paper look a better fit for your brand identity?

Cost–Lifecycle Considerations

Don't just look at the price per box. Consider the total cost over the packaging's life. A lighter material could save you a significant amount on shipping. A reusable package could create a new customer loyalty program. And avoiding future plastic taxes or fines is a direct saving.

Material Compatibility and Supplier Selection

Once you have a shortlist of materials, get samples. Test them with your actual product. Ship them across the country. See how they hold up. At the same time, vet your suppliers. Ask for their certifications. Inquire about their production capacity and lead times. A great supplier is a partner who can help you innovate and ensure a stable supply. This eliminates the uncertainty that holds so many businesses back.

What Are the Best Sustainable Packaging Solutions for My Industry?

Every industry has its own unique set of packaging challenges. A solution that works perfectly for a clothing brand will fail completely for a food company. Let's look at tailored suggestions for your specific sector.

The best solution depends on your industry. Food and cosmetics often require barrier protection, favoring glass or certified compostable films. E-commerce needs durable, lightweight materials like recycled cardboard. Fashion can use recycled poly mailers or glassine bags.

I’ve seen firsthand how important industry-specific knowledge is. For example, in the cosmetics and skincare world, sustainability is no longer a bonus; it’s a core requirement. Customers don't just read the ingredient list on a cream; they judge the jar it comes in. A premium brand using cheap plastic packaging creates a disconnect that hurts sales. The packaging must match the quality and values of the product inside. Below are some common starting points for major industries.

| Industry | Recommended Solutions & Considerations |

|---|---|

| Food & Beverage | Glass jars, aluminum cans, certified compostable pouches, FSC-certified paper wrappers. Key Consideration: Must be food-safe and often requires a barrier to protect against oxygen or moisture. |

| Cosmetics & Skincare | Glass bottles/jars, recycled PET plastic, FSC-certified paperboard boxes, refillable systems. Key Consideration: Needs a premium look and feel. Packaging must protect delicate formulas from light and air. |

| Fashion & Apparel | Recycled cardboard boxes, recycled paper mailers, glassine bags (instead of plastic), recycled poly mailers. Key Consideration: Durability for shipping is key. Minimize empty space with right-sized packaging. |

| E-commerce | Right-sized, recycled-content cardboard boxes, paper-based void fill (instead of bubble wrap), self-sealing mailers. Key Consideration: Focus on lightweighting to reduce shipping costs and carbon footprint. |

| Pet Products | Multi-layer recyclable bags (for food), compostable waste bags, molded pulp inserts for toys. Key Consideration: Durability and odor control are often important factors. |

| Household Goods | Refill pouches for cleaning supplies, concentrated pods, 100% recycled cardboard shippers. Key Consideration: Focus on reducing plastic waste through concentration and refill models. |

What Are the Biggest Myths About Sustainable Packaging?

There is a lot of misinformation about sustainable packaging. Believing these myths can prevent you from making a positive change that benefits your business and the planet. Let's bust a few of the most common ones.

The biggest myths are that sustainable packaging is always more expensive, that it's not strong enough to protect products, and that all "bio" materials are automatically good for the environment. These are often oversimplifications or completely untrue.

These myths create fear and uncertainty. I hear them from business owners all the time. But when we dig into the details, we almost always find a solution that works. The sustainable packaging industry has innovated so much in the past few years. The materials available today are stronger, more affordable, and more versatile than ever before. It's time to replace these old myths with current facts.

Myth 1: It's Always Too Expensive

This is the most common objection. While some innovative materials can have a higher upfront cost, many do not. Recycled cardboard, for example, is often cost-competitive with virgin materials. Furthermore, this myth ignores the total cost. Sustainable design can reduce shipping expenses through lightweighting. It can increase sales by attracting eco-conscious customers. And it can help you avoid costly government fines related to plastic waste.

Myth 2: It's Not Protective Enough

This is a leftover idea from the early days of eco-packaging. Today, sustainable materials are incredibly advanced. Molded pulp and mushroom packaging can provide shock absorption that is superior to styrofoam. Paper-based wraps can cushion fragile items just as well as plastic bubble wrap. The key is proper design and testing. I have helped companies ship everything from heavy glass bottles to delicate electronics using 100% plastic-free packaging.

Myth 3: "Biodegradable" and "Bio-Based" Are Always Better

These terms can be misleading. A "bio-based" plastic is made from plants, but it might not be biodegradable or recyclable. It could still end up in a landfill for centuries. "Biodegradable" is an unregulated term that doesn't specify a timeframe or environment. A package might biodegrade in 500 years. Instead, look for specific, certified terms like "Commercially Compostable" or "Home Compostable," which have clear standards to meet.

What Are the Challenges of Sustainable Packaging in 2026?

Switching to sustainable packaging is a smart move, but it's not always simple. Being aware of the potential challenges can help you plan ahead and avoid problems. Let's look at the real-world limitations.

The main challenges in 2026 are inconsistent recycling and composting infrastructure, potential supply chain disruptions for new materials, higher initial costs for some options, and lingering consumer confusion about proper disposal.

While the benefits are clear, it's important to be realistic. I always tell my clients to prepare for a few hurdles. One of the biggest is infrastructure. You might choose a fantastic, certified compostable material, but it doesn't help if your customers don't have access to a commercial composting facility. Another key area, as I've mentioned, is the supply chain. You must ensure your chosen supplier can meet your volume needs consistently.

Infrastructure Gaps

The ability to recycle or compost a material depends heavily on local infrastructure. What is easily recycled in one city might end up in a landfill in another. This is a major challenge for e-commerce brands that ship nationwide. The best approach is to choose materials that are widely recycled, like paper and cardboard, or to invest heavily in consumer education.

Supply Chain and Scalability

New and innovative materials can sometimes face supply chain issues. There might be only a few suppliers, leading to longer lead times or price volatility. As I always stress, before committing to a material, you must verify that your supplier can reliably produce the quantity you need, when you need it. Ask for their production capacity and do a small test run first.

Performance and Cost

While many sustainable materials perform just as well as plastic, some may have limitations. For example, some compostable films may not have the same shelf-life or moisture barrier properties. There can also be a "green premium" or higher cost for certain materials. Businesses must balance their sustainability goals with their budget and performance requirements.

Consumer Education

You can design the perfect recyclable or compostable package, but if the consumer throws it in the wrong bin, the effort is wasted. Clear, simple on-pack labeling and communication are essential. Use clear logos and simple language like "Recycle Me" or "Compost in a Commercial Facility."

How Can You Transition Your Business to Sustainable Packaging?

The idea of changing all your packaging can feel huge and complicated. This fear of the unknown is what stops most businesses from even starting. Let's break it down into a simple, step-by-step roadmap.

To transition, start by auditing your current packaging to identify problem areas. Then, set clear goals, research and test new materials with suppliers, and launch your new packaging with clear communication to educate your customers.

In my experience, having a clear plan like this eliminates 80% of the hesitation. Instead of a vague, scary goal, you have a series of manageable tasks. This process turns uncertainty into action. The most important first step is the audit. You can't improve what you don't measure. Get a clear picture of what you're using now, and you'll immediately see opportunities for easy wins.

A Step-by-Step Roadmap

- Audit Your Current Packaging: For each product, write down what packaging you use. Note the material type, weight, and size. Identify your biggest problems. Are you using too much plastic? Is there a lot of empty space in your boxes?

- Set Clear and Realistic Goals: You don't have to change everything overnight. Set a specific goal. For example: "By the end of the year, we will eliminate all plastic void fill" or "We will increase the recycled content in our boxes to 80%."

- Research Materials and Suppliers: Use the information in this guide to research alternatives. Contact potential suppliers and ask for samples and pricing. Remember to audit their supply chain reliability.

- Test, Test, Test: Once you have samples, test them thoroughly. Pack your products and ship them. Leave them on a shelf. Make sure the new packaging meets all your performance requirements.

- Develop a Budget: Calculate the total cost of the transition. This includes new material costs, any design fees, and potential changes to your packing process.

- Launch and Educate: When you launch your new packaging, tell your customers about it. Explain why you made the change and how they can dispose of the new packaging correctly. This turns a simple operational change into a powerful marketing story.

What Sustainable Packaging Certifications Matter in 2026?

Certifications can look like a confusing mix of letters and logos. But using the right ones builds trust and proves your commitment to sustainability. They show you've done the work.

Key certifications for 2026 include FSC or PEFC for responsibly sourced paper, BPI or OK Compost for compostability, and USDA BioPreferred for bio-based content. These third-party seals provide credible proof of your sustainability claims.

Think of certifications as a shortcut for trust. They tell your customers that an independent organization has verified your claims. This is far more powerful than just saying "eco-friendly" on your box. It protects you from accusations of greenwashing and gives customers confidence in their purchase. When choosing a supplier, always ask which certifications they hold for their materials.

| Certification | What It Means | When It's Used |

|---|---|---|

| FSC (Forest Stewardship Council) | Guarantees that paper and wood products come from responsibly managed forests that provide environmental, social, and economic benefits. | For any paper or cardboard packaging, including boxes, inserts, and labels. |

| PEFC (Programme for the Endorsement of Forest Certification) | A similar global certification to FSC, also ensuring sustainable forest management. | Also used for paper and cardboard products. Some regions may have more PEFC-certified forests. |

| BPI (Biodegradable Products Institute) | Certifies that a product is compostable in a commercial or industrial composting facility, meeting ASTM D6400 standards. | For compostable plastics (like PLA), bags, and food service ware in North America. |

| OK Compost / EN 13432 | The European standard for commercial compostability. "OK compost HOME" certifies that a product can be composted in a backyard bin. | For any product marketed as compostable in Europe. |

| USDA BioPreferred | Verifies that a product is composed of a certain percentage of bio-based (plant-derived) content. | For bio-based plastics and other materials to show they reduce reliance on fossil fuels. |

| EU / FDA Food-Contact | These are not sustainability certifications, but they are critical safety regulations. They ensure that the packaging material is safe to come into direct contact with food. | Absolutely essential for any food and beverage packaging. |

What Is the Future of Sustainable Packaging Beyond 2026?

The world of sustainable packaging is changing fast. To stay ahead, you need to know what's coming next. Let's look at the most exciting trends on the horizon.

The future of packaging is smart, circular, and radically efficient. We'll see more refillable systems, AI-optimized designs, advanced compostable materials from new sources, and smart labels that help with sorting and recycling.

Innovation in this space is incredible. What seems futuristic today will be standard practice in a few years. The main goal is to move beyond simply "less bad" packaging and toward creating systems that are actively good for the planet. This means designing out waste from the very beginning. For businesses, this is an opportunity to lead, innovate, and build a truly resilient brand for the future.

Refillable and Reusable Systems

The most sustainable package is the one that is never thrown away. More brands will adopt models where customers buy a durable container once and then purchase refills, often in lightweight pouches or pods. This will become common in household goods, personal care, and even food.

AI Optimization

Artificial intelligence will be used to design packaging that uses the absolute minimum amount of material needed. AI can run thousands of simulations to create a lighter, stronger box, and it can also optimize shipping logistics to reduce the overall carbon footprint of a product's journey.

Advanced Compostable Materials 2.0

We will see new compostable materials made from sources like seaweed, mushrooms (mycelium), and agricultural waste. These next-generation materials will have better barrier properties for protecting food and will be designed to compost more easily in a wider range of conditions.

Smart Packaging

Packaging will become intelligent. QR codes could link to detailed information about the product's journey and disposal instructions. Tiny sensors or chemical markers could help automated sorting facilities identify different material types with near-perfect accuracy, dramatically improving recycling rates.

How Can You Reduce Packaging Waste Even More?

Choosing a sustainable material is a fantastic first step. But you can still be wasteful even with the best materials. Here are some strategies to reduce your packaging footprint even further.

Beyond material choice, you can reduce waste by lightweighting (using less material), optimizing your design to eliminate empty space, and educating your customers on how to properly reuse, recycle, or compost the packaging they receive.

This is about adopting a "less is more" philosophy. I've seen companies cut their packaging material usage by 30% just by redesigning their boxes to be a better fit for their products. This not only reduces waste but also saves a significant amount of money on materials and shipping. Every gram of material you can remove from your packaging adds up to a huge positive impact over thousands of shipments.

Lightweighting

This is the process of reducing the weight and thickness of your packaging without compromising its protective function. This could mean using a slightly thinner grade of cardboard or switching from a heavy glass jar to a lighter, recycled plastic or aluminum option. Less weight means lower shipping costs and a smaller carbon footprint.

Design Optimization

This is often called "right-sizing." The goal is to make your packaging fit your product like a glove, eliminating the need for excessive void fill like bubble wrap or air pillows. This creates a better unboxing experience for the customer and is a very visible sign that your company is conscious about waste.

Digital Printing

Instead of using large, wasteful labels, consider printing information directly onto your packaging. Modern digital printing techniques can print high-quality graphics and text on-demand, reducing the need for extra materials and adhesives that can complicate the recycling process.

Improving Recycling Rates

Your responsibility doesn't end when the package ships. You can play an active role in making sure it gets recycled. Use the standardized How2Recycle label to provide clear, simple instructions. Use your website and social media to educate your customers about how to dispose of your packaging correctly in their local area.

Conclusion

Making the switch to sustainable packaging is essential for your brand's future. It's what your customers expect, regulators demand, and our planet needs. A clear, step-by-step plan makes it achievable.