Finding affordable, simple, and effective packaging is hard. Poor packaging can damage your product and brand image. Tuck boxes are a versatile and cost-effective solution1 for many businesses.

A tuck box is a common type of paperboard box2. It has a top flap and/or a bottom flap that "tucks" in to close the box. This simple design makes it cost-effective, easy to assemble, and highly customizable for a wide range of products.

I've seen countless brands struggle with their packaging choices3. It's a critical part of the customer experience4, yet it's often an afterthought. From my manufacturing perspective, tuck boxes5 are a game-changer when you understand their potential. They are one of the most efficient packaging options for brands that need to balance cost, customization, and speed. Let's break down exactly what they are and why they might be the perfect fit for your business.

What Is a Tuck Box, Really?

You hear the term "tuck box" but don't know what it means. This confusion stops you from choosing the right packaging. Let's define it simply so you can make a better choice.

A tuck box is a folding carton made from a single piece of paperboard. It features flaps on one or both ends that tuck into the box to close it without tape or glue. This design is simple, efficient, and very common for retail products.

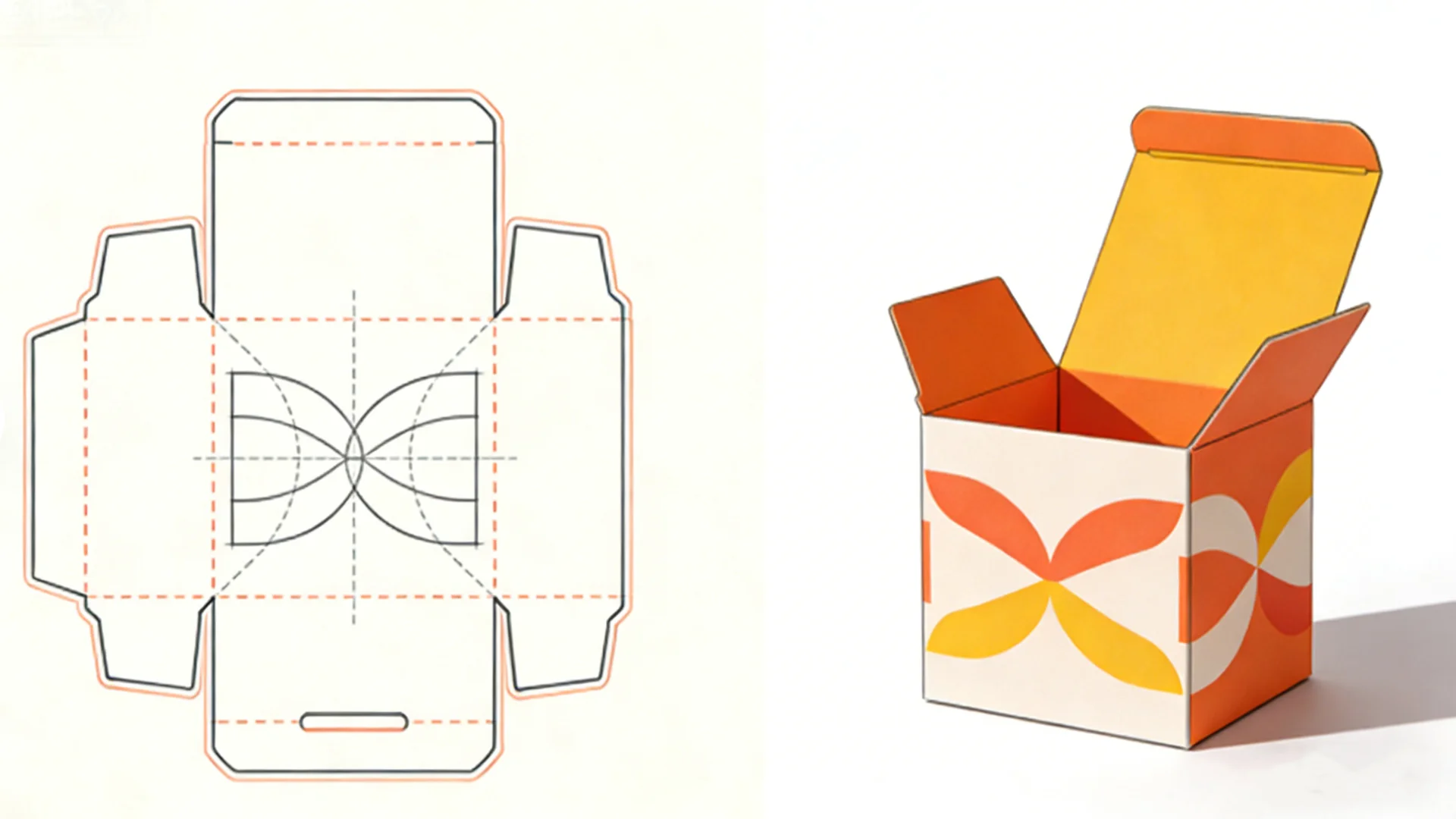

When I talk about a tuck box, I'm talking about a very specific and clever design. It all starts as a single, flat piece of paperboard. A machine cuts this sheet into a specific shape, which we call a die-cut. At the same time, it creates creases or scores where the box needs to be folded.

The Basic Structure

The core of the design is the "tuck flap." This is the main flap on the top or bottom that has a small, extra tab. This tab tucks into the main body of the box. The friction between the tab and the box walls holds it securely closed. You don't need any glue, tape, or staples to seal it for display on a shelf. This makes the unboxing experience6 clean and easy for the customer.

How It Assembles

Because it's made from one piece and pre-scored, assembly is incredibly fast. In our factory, we ship them flat to save our clients on shipping costs and storage space. When they arrive, a worker can fold and assemble one in just a few seconds. This efficiency is a huge advantage when you're packing hundreds or thousands of products. The simplicity of the structure allows for faster production runs and lower tooling costs on our end, a saving we pass on to our customers.

Why Are Tuck Boxes So Popular in Packaging?

You want packaging that is cheap, fast, and looks good. Finding all three is a challenge. Tuck boxes deliver on all fronts, making them a top choice for so many brands.

Tuck boxes are popular because they offer a perfect balance of cost, speed, and customization. Their simple, one-piece design makes them cheap to produce and easy to assemble. They also provide ample flat surface area for high-quality printing, boosting brand appeal without high costs.

From a manufacturing viewpoint, the popularity of tuck boxes5 is no surprise. They solve three of the biggest packaging problems7 for businesses: budget, time, and branding8. I've worked with so many clients who are amazed at how this simple box style can transform their operations and their shelf presence.

Cost-Effectiveness

The design is incredibly efficient. Since it's cut from a single sheet of paperboard, there is very little material waste. The tools needed to cut them, called dies, are less complex than those for other box styles. This lowers the setup cost for a new project. They also ship flat, which drastically reduces shipping and warehousing costs. I remember a client who switched from a rigid box to a tuck box for their soap. Their packaging cost9 dropped by 40%, and they cut their packing time in half.

Speed and Efficiency

Time is money, especially in fulfillment. Tuck boxes are designed for rapid assembly. Anyone can learn to fold one in under a minute. This means your team can pack products faster, which lowers labor costs and gets your product to market quicker. This speed is a huge benefit whether you're a small startup packing orders in your garage or a large company with a dedicated fulfillment center.

Customization and Branding

A tuck box is like a blank canvas. The flat, smooth paperboard surfaces are perfect for printing. You can print vibrant colors, sharp logos, and detailed product information. You can also add special finishes like a gloss or matte coating, foil stamping, or embossing to create a premium feel. This allows a brand to create a high-end look without the high cost of more complex packaging.

What Are the Main Types of Tuck Boxes?

One "tuck box" style doesn't fit all. Choosing the wrong type can lead to damaged products or a frustrating customer experience4. Knowing the main types helps you pick the perfect one.

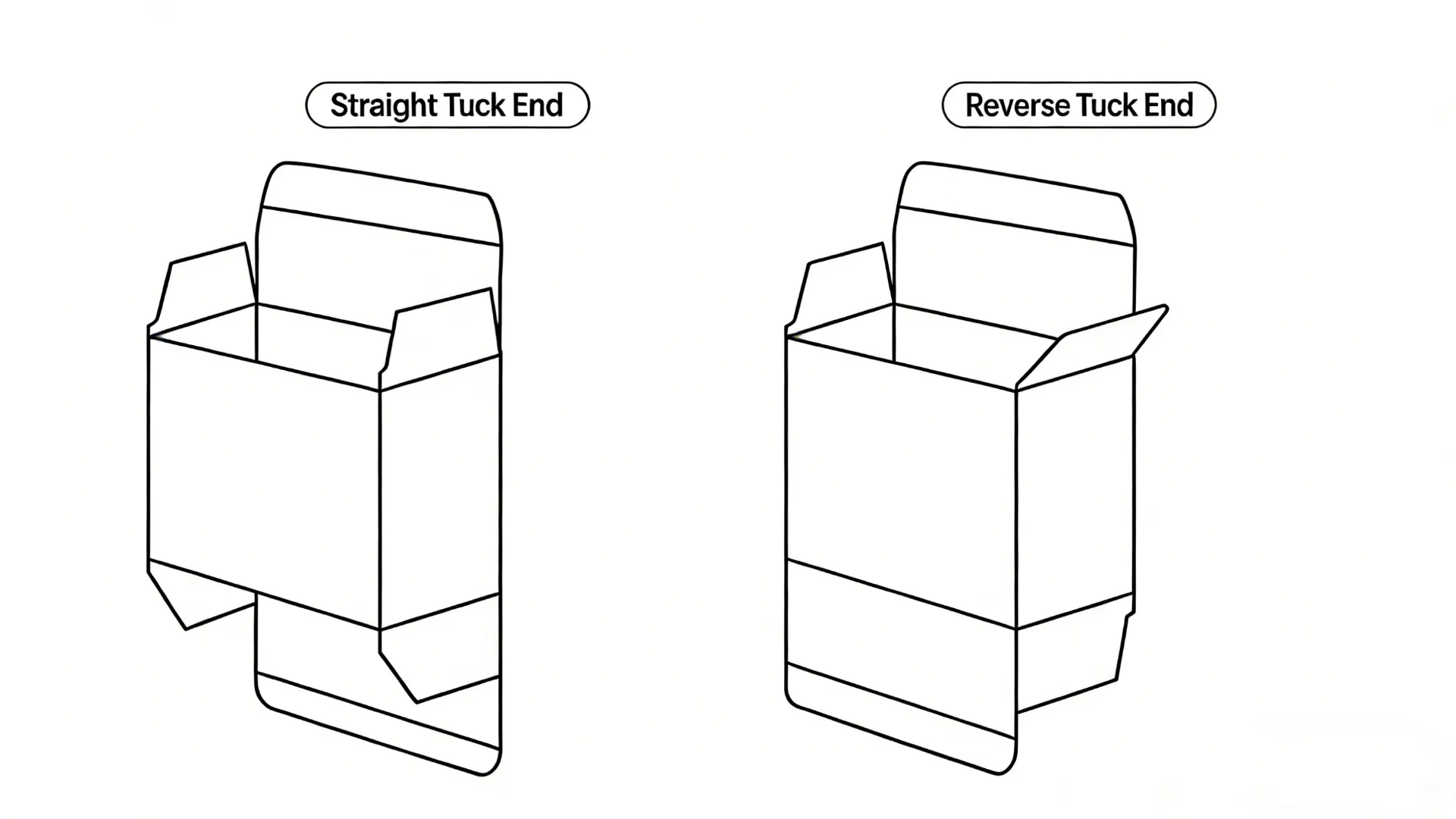

The two main types are the Straight Tuck End (STE)10 and the Reverse Tuck End (RTE)11. The STE has flaps on the same side, creating a cleaner look. The RTE has flaps on opposite sides, which is often more structurally sound and cost-effective to produce.

While the basic idea of a tuck flap is simple, there are a few key variations that serve different purposes. Choosing the right one depends on your product's weight, your budget, and the look you want to achieve. In our experience, most products fall into one of these three categories.

Straight Tuck End (STE)10

In an STE box, the tuck flaps on the top and bottom both fold from the front to the back (or vice-versa). This creates a very clean and seamless front panel because the raw edges of the side flaps are hidden. This style is often used for luxury or cosmetic products where appearance is critical. However, it can be slightly more expensive to produce because it doesn't use the paperboard sheet as efficiently as an RTE box.

Reverse Tuck End (RTE)11

This is the most common and economical style. In an RTE box, the top flap tucks from the back to the front, and the bottom flap tucks from the front to the back. This "reverse" layout allows the die-cut shapes to nest more tightly together on a large sheet of paperboard, reducing waste. This makes it a cheaper option. It's strong, reliable, and the workhorse of the tuck box world.

Snap Lock Bottom12 (Tuck Top)

This is a hybrid style, also called a 1-2-3 bottom. It has a standard tuck top, but the bottom is made of four flaps that interlock to create a much stronger base. This is the best choice for heavier items like glass jars, candles, or small electronics. While it takes a few seconds longer to assemble the bottom, it provides extra security and peace of mind that your product won't fall through.

| Feature | Straight Tuck End (STE)10 | Reverse Tuck End (RTE)11 | Snap Lock Bottom12 |

|---|---|---|---|

| Best For | Lightweight, luxury items | General purpose, most products | Heavier items, bottles |

| Appearance | Very clean front panel | Standard, functional | Standard top, secure base |

| Cost | Higher | Most economical | Moderate |

| Strength | Good | Good | Excellent (for base) |

Which Industries Use Tuck Boxes the Most?

You're not sure if a tuck box is right for your industry. Seeing how others use them gives you confidence. Here are the most common applications where we see them succeed.

Tuck boxes are used everywhere. You'll find them in cosmetics for things like lipstick and creams. They are used in food for tea bags and small snacks. The electronics industry uses them for cables and small accessories. They are also perfect for pharmaceuticals and health products.

Over the years, I've seen tuck boxes5 adapted for nearly every industry imaginable. Their versatility is their greatest strength. They are a reliable go-to choice because they can be easily adjusted in size, material thickness, and print design to meet specific needs. Here are some of the biggest sectors that rely on them.

Cosmetics and Beauty

This industry is all about presentation. Tuck boxes are perfect for items like lipstick, foundation, serums, and lotions. The smooth surface allows for beautiful, high-resolution printing and premium finishes like foil stamping. The Straight Tuck End (STE)10 style is particularly popular here because it provides a clean, uninterrupted front panel for branding8.

Food and Beverage

You see tuck boxes5 all the time in the grocery store. They are used for tea bags, granola bars, chocolates, and other small, dry goods. They protect the product while acting as a mini-billboard on the shelf. For food products, we often use paperboard with special coatings to ensure it's food-safe and provides a barrier against moisture or grease.

Electronics and Accessories

Think about the last time you bought a phone charger, a cable, or a set of earbuds. It likely came in a tuck box. For these smaller, relatively lightweight items, a tuck box provides adequate protection at a very low cost. The box also has plenty of space to print technical specifications and instructions.

Health and Wellness

The pharmaceutical and wellness industries rely heavily on tuck boxes5 for things like vitamins, supplements, tinctures, and over-the-counter medicines. The packaging needs to be clean, professional, and have a lot of room for text. Tuck boxes deliver this perfectly. They also allow for features like tamper-evident seals to be easily added.

How Do You Choose the Right Tuck Box for Your Product?

Choosing the wrong box size or material can be a disaster. Products get damaged and money is wasted. Follow these simple steps I give my clients to get it right every time.

First, measure your product accurately (length, width, height). Add a small amount of wiggle room. Next, consider your product's weight to choose the right paperboard thickness. Finally, think about your brand's look to decide on the printing and finishing options you need.

In our experience, most issues with packaging performance come not from the box style itself, but from mismatched materials or incorrect size planning. A great design can fail if the box is too big or the paperboard is too thin. Getting these details right from the start is the key to success.

Step 1: Measure Your Product

Get a ruler or calipers and measure the length, width, and height of your product at its widest points. Don't guess. Once you have the exact dimensions, add about 1/8 inch (or 3mm) to each dimension. This small bit of extra space makes it easy to get the product in and out of the box without it being too loose. A snug fit is the goal.

Step 2: Determine the Material Weight

The weight of your product determines the thickness of the paperboard you need. Paperboard thickness is measured in points (pt). A higher number means a thicker, more rigid board. This is a critical step. Using a board that is too thin is the most common mistake I see.

| Product Weight | Recommended Paperboard | Common Use |

|---|---|---|

| Under 0.5 lbs (225g) | 16-18 pt | Cosmetics, Tea Bags |

| 0.5 - 1 lb (225-450g) | 18-24 pt | Soaps, Electronics |

| Over 1 lb (450g) | 24 pt+ or Snap Lock Bottom12 | Candles, Jars |

Step 3: Consider Unboxing and Branding

Finally, think about the customer experience4. Do you want a premium, clean look? A Straight Tuck End (STE)10 box might be best. Are you on a tight budget? A Reverse Tuck End (RTE)11 is more economical. Does your product have some weight to it? A Snap Lock Bottom12 provides security. This is also when you decide on your printing and finishes. Do you want a natural, earthy look with a matte finish, or a bright, bold look with a gloss finish? Planning this now ensures your final package matches your brand identity.

Should You Choose a Custom or Standard Tuck Box?

You need boxes now, but also want them to look unique. Should you go with a standard size or a fully custom one? This decision impacts your cost, timeline, and branding8.

Standard tuck boxes5 are pre-sized, cheaper, and available faster, but offer limited branding8. Custom tuck boxes5 are made to your exact size and design specifications. They cost more and take longer but provide a perfect fit and a unique brand experience for your customers.

This is a question I get all the time. The answer really depends on what stage your business is in and what your priorities are. Both options are great, but they serve different needs. It's a classic trade-off between speed and cost versus a perfect, branded fit.

The Case for Standard Boxes

Standard boxes, sometimes called stock boxes, are mass-produced in common sizes. Their biggest advantage is speed and low cost, especially for small quantities. If you're just starting out, testing a new product, or need packaging immediately, a standard box is a fantastic option. You can order as few as 50 or 100 at a time. The downside is that the fit might not be perfect for your product, and your branding8 is usually limited to a sticker or label.

The Power of Custom Boxes

Custom boxes are designed and manufactured specifically for your product. You control everything: the exact dimensions, the type and thickness of the paperboard, the printing, and any special finishes. This ensures a perfect fit, which not only looks more professional but also provides better protection. It creates a memorable unboxing experience6 that reinforces your brand. The trade-off is a higher minimum order quantity (usually 500 or more) and a longer lead time for production. We often advise new businesses to start with a standard box and then move to a custom one as they scale.

| Factor | Standard Box | Custom Box |

|---|---|---|

| Product Fit | Generic, may be loose | Perfect, snug fit |

| Branding | Limited (usually labels) | Full creative control |

| Cost per unit | Higher at low volume | Lower at high volume |

| Minimum Order | Very low (e.g., 50) | Higher (e.g., 500+) |

| Speed | Fast, ships immediately | Slower (weeks for production) |

What Are Some Frequently Asked Questions About Tuck Boxes?

You still have questions about tuck boxes5. Getting clear answers is hard. I've gathered the most common questions I hear from clients and answered them for you right here.

People often ask about the minimum order quantity, which varies by supplier. They also ask if tuck boxes are eco-friendly; they usually are, as they're made from recyclable paperboard. Another common question is about lead times, which are typically a few weeks for custom orders.

Even with all this information, people usually have a few more specific questions before they place an order. Here are the answers to the ones that come up most often in my conversations with brands.

Are tuck boxes durable?

The durability of a tuck box depends entirely on the thickness of the paperboard used. A box made from 16pt stock is great for a very light item like a lip balm, but it would not be suitable for a heavy glass candle. When you choose the correct paperboard thickness for your product's weight, a tuck box is very durable for retail use. However, it's important to remember they are not designed to be shipping boxes. They should always be placed inside a stronger corrugated shipping box to be mailed.

Can I get a sample before placing a large order?

Absolutely. I always recommend this. Most packaging manufacturers, including us, can provide a sample. This can be a "structural sample," which is an unprinted box made to your exact dimensions so you can test the fit with your product. We can also provide a "printed sample," which is a fully finished version of your box. This allows you to check the print quality and colors before committing to a full production run.

What's the difference between paperboard and corrugated?

This is a key distinction. Paperboard (also called cardstock or carton) is a single layer of thick paper material. This is what tuck boxes are made from. It's smooth, great for printing, and ideal for retail packaging. Corrugated material has three layers: two flat outer layers with a wavy, fluted layer in the middle. This structure gives it much more strength and cushioning, which is why it's used for shipping boxes. You put your paperboard tuck box inside a corrugated shipping box.

Conclusion

Tuck boxes are a versatile, cost-effective, and customizable packaging choice. By understanding the types and choosing the right specifications, you can create professional packaging that protects your product.

Discover various strategies for finding affordable packaging options that don't compromise quality. ↩

Understand the versatility of paperboard boxes and how they can be utilized across various industries. ↩

Get insights into the key considerations for selecting the right packaging for your products. ↩

Explore the connection between packaging design and customer satisfaction. ↩

Explore the advantages of tuck boxes, including cost-effectiveness and customization options for your products. ↩

Learn how thoughtful packaging design can create memorable unboxing experiences that delight customers. ↩

Identify typical packaging challenges and how to overcome them for better product protection. ↩

Explore the crucial role of packaging in shaping brand identity and influencing customer choices. ↩

Discover effective strategies to minimize packaging costs while maintaining high standards. ↩

Learn about the features and benefits of STE boxes for luxury and cosmetic products. ↩

Discover why RTE boxes are a popular choice for many businesses due to their cost-effectiveness. ↩

Understand the benefits of Snap Lock Bottom boxes for heavier items and their secure design. ↩