Choosing between kraft1 and cardboard%%%FOOTNOTE_REF2%%% feels confusing. The wrong box can lead to surprise costs and [production delays](https://en.wikipedia.org/wiki/Bottleneck(production))3, eating into your profits. Let's make the right choice together.

Choose kraft1 for a natural look, lightweight4 items, and direct printing. Pick corrugated cardboard2 for strength, shipping protection5, and heavier products. Your decision should balance branding6, product needs, and supply chain7 realities. It's about more than just looks; it's about performance.

I've seen so many businesses get this wrong. They pick a box based on a Pinterest photo, only to find out it crushes during shipping or won't work on their assembly line. It's a costly mistake. But it's an easy one to avoid once you know what to look for. So, let's break down why this choice is so critical for your business's health.

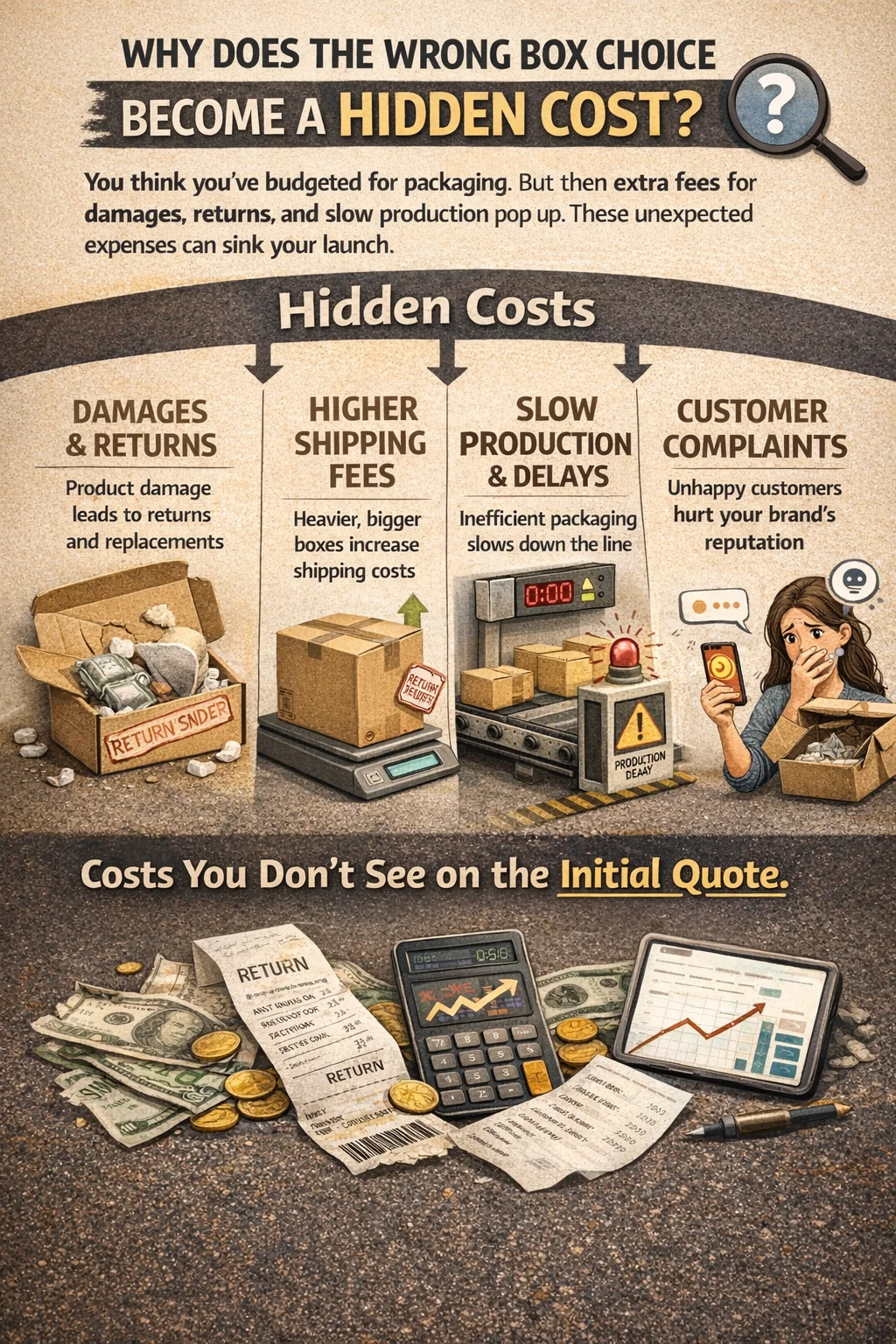

Why Does the Wrong Box Choice Become a Hidden Cost?

You think you've budgeted for packaging. But then extra fees for damages, returns, and slow production pop up. These unexpected expenses can sink your launch.

The wrong box increases costs through product damage8, higher shipping fees for weight4 or size, and production line slowdowns. It also leads to customer complaints9 and returns, which directly impact your revenue and brand reputation. These are costs you don't see on the initial quote.

From my experience, hidden costs10 are where a packaging budget11 truly breaks. It's never the unit price of the box that gets you; it's the downstream effects. I worked with a client who chose a sleek but flimsy box for their new skincare line. They saved a few cents per box, but the problems started immediately.

Production Line Friction

The boxes were too weak for the automated packing machine, causing constant jams. This slowed down their entire production schedule, leading to overtime labor costs and delayed shipments to retailers. A stable production process is paramount, and the box is a key component of that.

Shipping Inefficiencies

The weak boxes couldn't be stacked on pallets without crushing the ones at the bottom. This meant they had to ship more, smaller pallets, which increased their freight costs.

The Cost of a Bad Experience

Worst of all, about 10% of the products arrived damaged to the customer. The cost of replacing the product, the new shipping fees, and the customer service12 hours spent handling complaints completely erased their initial savings. The best packaging choice is one that performs reliably from the factory to the customer's hands.

| Hidden Cost Area | Impact of the Wrong Box |

|---|---|

| Product Damage | Increased returns, replacement costs, lost inventory. |

| Shipping | Higher fees from dimensional weight4 or inability to stack. |

| Labor | Slower packing lines, manual handling, customer service12 time. |

| Brand Reputation | Negative reviews from damaged goods and poor unboxing. |

Kraft vs. Cardboard: What Are the Real Differences That Matter?

Kraft and cardboard2 look similar, so you might think they're interchangeable. This assumption can lead to damaged products and unhappy customers. Let's clarify the key distinctions.

Kraft paper is a single-ply, lightweight4 material made directly from wood pulp, ideal for an earthy look. Corrugated cardboard2 has three layers: two flat linerboards with a ruffled "flute" in between. This structure gives cardboard2 superior strength and cushioning for shipping and heavier items.

Let's get into the details, because this is where the right decision is made. I always tell my clients to think of it like building a house. You wouldn't use the same material for a decorative wall panel as you would for the structural foundation.

The Anatomy of Cardboard

Corrugated cardboard2 is an engineered material. It consists of two flat sheets of paper, called linerboard, with a wavy, fluted layer sandwiched between them. This fluted paper is what creates air pockets that provide cushioning and incredible structural rigidity. It’s designed to resist impact and pressure from all sides. The thickness of this flute (like B-flute or E-flute) can be adjusted to balance protection and sleekness. This structure is why cardboard2 is the go-to choice for shipping.

The Simplicity of Kraft

Kraft paper, on the other hand, is basically a very strong, single sheet of paperboard. Its name comes from the German word for "strength." It's made from virgin wood pulp, which has long fibers that give it high tear resistance. It’s great for folding into boxes for lightweight4 goods, but it has no built-in cushioning. It protects from scratches and dust but offers very little protection from drops or crushing.

| Feature | Kraft Box | Corrugated Cardboard Box |

|---|---|---|

| Structure | Single layer of paperboard | 3+ layers (2 linerboards, 1 flute) |

| Primary Strength | Tear resistance | Crushing and impact resistance |

| Cushioning | Very low | High (due to air pockets in flute) |

| Best Use Case | Lightweight4 products, retail packaging | Shipping, fragile or heavy items |

Cost Comparison: Why Isn’t It Just About Unit Price?

You found a box with a low unit price and feel like you've won. But total cost13 includes shipping, damages, and storage. Your "cheap" box might be the most expensive.

The true cost of a box goes beyond the per-unit price. You must factor in shipping weight4, potential for product damage8 and returns, and storage space required. A slightly more expensive but lighter or stronger box can save you significant money in the long run.

I can't stress this enough: you must calculate the total landed cost per unit. I had a client selling gourmet food baskets. They were choosing between two boxes. Box A was $1.50 per unit. Box B was a stronger, custom-fit design that cost $1.80. They were leaning toward Box A to save $0.30 per unit.

The Unit Price Trap

On the surface, saving $0.30 on 10,000 units looks like an easy $3,000 in savings. But this view is dangerously incomplete. We had to dig deeper.

Calculating Landed Cost

Box A was heavier and larger. Because of its dimensions and weight4, the shipping cost was $12.50. Box B, being lighter and perfectly sized, shipped for only $10.00. That's a $2.50 savings on shipping alone. Furthermore, Box A had a 5% damage rate because the items shifted around. For their $50 basket, that 5% damage rate added an average cost of $2.50 per unit shipped ($50 * 5%). Box B's damage rate was near zero.

Let's look at the real math:

| Cost Factor | Box A (Cheaper Unit Price) | Box B (Higher Unit Price) |

|---|---|---|

| Unit Price | $1.50 | $1.80 |

| Shipping Cost | $12.50 | $10.00 |

| Damage Cost | $2.50 | $0.00 |

| Total Cost/Unit | $16.50 | $11.80 |

The "cheaper" box was actually $4.70 more expensive for every single order they shipped. The choice became obvious once we looked at the whole picture.

Printing & Customization: What Works and What Doesn’t?

You have a beautiful brand design. But printing it on the wrong box material can look cheap and smudged. This can ruin your unboxing experience.

Kraft paper’s smooth, natural surface is great for simple, one or two-color designs using flexographic printing14. Corrugated cardboard2 can be printed on directly, but for high-quality, full-color graphics, it's best to print on a separate top sheet (litho-lamination15) and apply it to the box.

The material you choose directly impacts how your brand is presented. A great design on the wrong canvas can look amateurish. I've seen brands spend a fortune on design only to have it look blotchy and unprofessional on the final box.

Direct Printing on Kraft

Kraft paper is a fantastic surface for a certain aesthetic. Because it's a smooth, single sheet, it takes ink very cleanly. It is perfect for one or two-color logos that aim for a rustic, organic, or minimalist feel. Think of a local coffee roaster or an Etsy artisan. The natural brown of the kraft1 paper becomes part of the design itself. This is usually done with flexographic printing14, which is cost-effective for large runs.

The Challenge of Corrugated Surfaces

Printing directly onto a standard corrugated shipping box is more difficult. The surface is more uneven due to the fluting underneath. For simple text or a one-color logo, flexographic printing14 works fine. However, if you try to print multiple colors or detailed images, they can look fuzzy and misaligned. For a better finish, you can use a box made with a white outer liner, which provides a better canvas.

High-End Finishes: Litho-Lamination

For a truly premium, retail-ready look on a strong corrugated box, the best method is litho-lamination15. We print your beautiful, full-color design on a separate, high-quality sheet of paper (like a poster). Then, we laminate, or glue, that printed sheet onto the corrugated board before it’s cut. This gives you the best of both worlds: photo-quality graphics and the structural protection of corrugated.

| Factor | Kraft Printing | Corrugated Printing |

|---|---|---|

| Best For | Rustic, 1-2 color designs | Protection-focused, high-end graphics |

| Method | Flexography (direct) | Flexography or Litho-lamination |

| Appearance | Natural, organic | Can be basic or photo-realistic |

| Cost | Low to moderate | Low (Flexo) to High (Litho) |

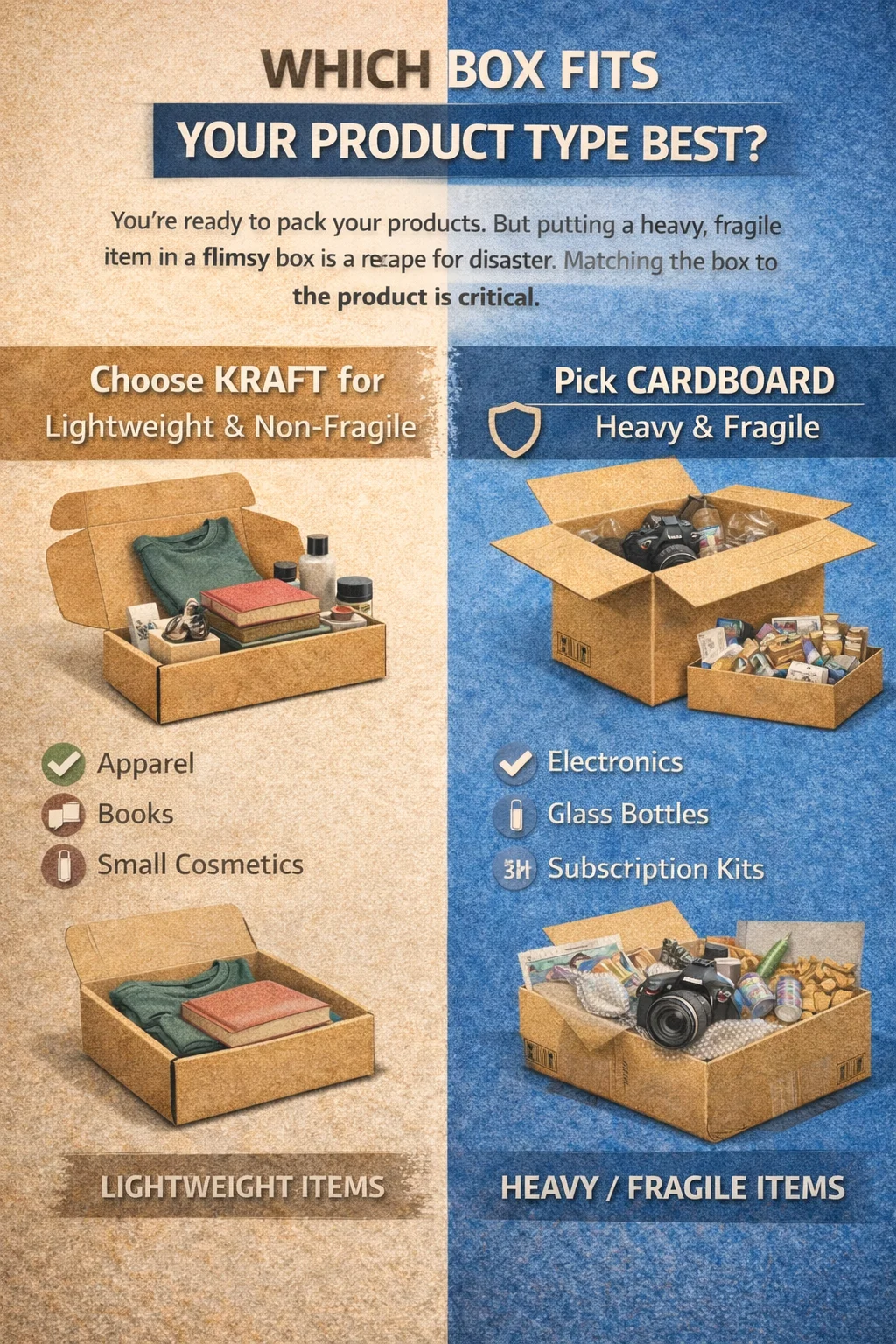

Which Box Fits Your Product Type Best?

You're ready to pack your products. But putting a heavy, fragile item in a flimsy box is a recipe for disaster. Matching the box to the product is critical.

Kraft boxes are excellent for lightweight4, non-fragile items16 like apparel, books, or small cosmetics. Corrugated cardboard2 boxes are necessary for anything heavy, fragile, or irregularly shaped, such as electronics, glass bottles, home goods, or subscription box kits that need protection during shipping.

This seems obvious, but it's a mistake I see all the time. The first question I ask a new client is always about the product itself. The product dictates the packaging, not the other way around. Let's break it down into simple categories.

The Lightweight4 Champions (Kraft)

If your product is light and not easily broken, a kraft1 box can be a great choice. It provides a nice presentation and basic protection against scuffs and dirt.

- Examples: T-shirts, scarves, notebooks, prints, small cosmetics in durable containers, and other soft goods.

- Why it works: These products don't need cushioning from drops. The primary goal is containment and a pleasant unboxing experience. A kraft1 mailer box is often perfect.

The Heavy-Duty Protectors (Cardboard)

If your product is fragile, heavy, or has an awkward shape, you need corrugated cardboard2. There is no substitute for its structural integrity.

- Examples: Ceramic mugs, glass candles, electronics, wine bottles, kitchen appliances, and curated subscription boxes with multiple items.

- Why it works: The fluting in the cardboard2 absorbs shock and resists crushing forces during transit. For very fragile items16, you would use a corrugated box combined with a custom corrugated insert to hold the product securely in place.

| Product Category | Recommended Box | Why? |

|---|---|---|

| Apparel & Soft Goods | Kraft Box | Lightweight4 and non-fragile. Focus is on branding6. |

| Glass & Ceramics | Corrugated Box | Product is fragile and needs cushioning and crush protection. |

| Electronics | Corrugated Box | Product is fragile, often heavy, and high-value. |

| Subscription Box | Corrugated Box | Must protect multiple, varied items from shifting and impact. |

Shipping & Storage: What Is the Supply Chain Reality?

Your boxes look great. But they get crushed in the warehouse or cost a fortune to ship. Ignoring logistics will destroy your margins and cause major operational headaches.

In the supply chain7, corrugated cardboard2 is king. It stacks well without crushing, protecting inventory during storage. It also withstands the rough handling of shipping carriers. Kraft boxes, being less rigid, are better for "box-in-a-box" scenarios or for shipping durable goods in mailer bags.

From a manufacturing and supply chain7 perspective, this is the most important part of the decision. A box's journey is rough. It gets handled by machines, stacked under hundreds of pounds of other boxes, and exposed to moisture.

The Stacking Test

This is where corrugated boxes prove their worth. Their structure is specifically designed to support weight4. You can stack pallets of corrugated boxes high in a warehouse, maximizing your storage space and keeping inventory safe. If you try to stack kraft1 boxes, the ones at the bottom will buckle and collapse. I once visited a warehouse where a client had used the wrong boxes; an entire pallet of their product had collapsed, costing them thousands in lost inventory.

Surviving the Shipping Gauntlet

From the warehouse, your box goes on a truck, then to a sorting facility with miles of conveyor belts and chutes, then onto another truck or plane. This process is automated and violent. Corrugated cardboard2 is built to withstand punctures, bumps, and short drops. A kraft1 box is essentially just paper; it tears and punctures much more easily.

Talk to Your Supplier

Before you finalize any material, have a short discussion with your factory and your fulfillment center. Ask them: "Will this box work with your equipment? Does it meet your standards for stacking and shipping?" They are your partners. They know what works and what fails. This simple conversation can prevent incredibly costly mistakes.

| Performance Metric | Kraft Box | Corrugated Cardboard Box |

|---|---|---|

| Stacking Strength | Low | High |

| Puncture Resistance | Low | High |

| Impact Cushioning | Very Low | High |

| Supply Chain Suitability | Poor for palletizing | Excellent |

Sustainability: What’s Real vs. What’s Just Marketing?

You want to be eco-friendly. But many "green" claims are just marketing fluff. Choosing a truly sustainable option requires looking beyond the buzzwords.

Both kraft1 and corrugated cardboard2 are highly recyclable and often made from recycled content. Kraft paper often uses fewer chemicals and less bleaching, giving it a more "natural" profile. However, a durable, reusable cardboard box that prevents product damage (and re-shipping) can sometimes be the more sustainable choice.

Sustainability in packaging is a complex topic, and it's easy to get misled by marketing. Both kraft and corrugated are good choices from a materials standpoint. They are paper-based, biodegradable, and widely recycled.

Recycled Content and Recyclability

Both materials are part of a healthy circular economy. Kraft paper is often celebrated for being unbleached, which means fewer chemicals are used in its production. Corrugated cardboard, especially for shipping boxes, typically contains a very high percentage of post-consumer recycled content. In North America, the recycling rate for corrugated boxes is over 90%, which is fantastic.

The "Natural" Fallacy

Kraft paper's brown, earthy look makes it feel more sustainable, and sometimes it is. But this can be a trap. Don't let the look of the material trick you into making a poor functional choice.

The Bigger Picture: Reducing Waste

I always argue that the most sustainable package is the one that works. Think about it: if you choose a flimsy kraft box and 5% of your products break in transit, you have created immense waste. You've wasted the product itself, the original packaging, the fuel used to ship it, and the fuel and new packaging needed to ship the replacement. A slightly heavier corrugated box that ensures a 99.9% success rate is far more sustainable in practice. The goal is to minimize total waste, not just to use a material that looks "green."

| Sustainability Factor | Kraft Paper | Corrugated Cardboard |

|---|---|---|

| Recyclability | High | High (one of the most recycled materials) |

| Recycled Content | Varies, can be high | Typically very high (70-100%) |

| Production | Often unbleached (less chemical use) | Engineered for strength and durability |

| True Impact | Depends on preventing product waste | Depends on preventing product waste |

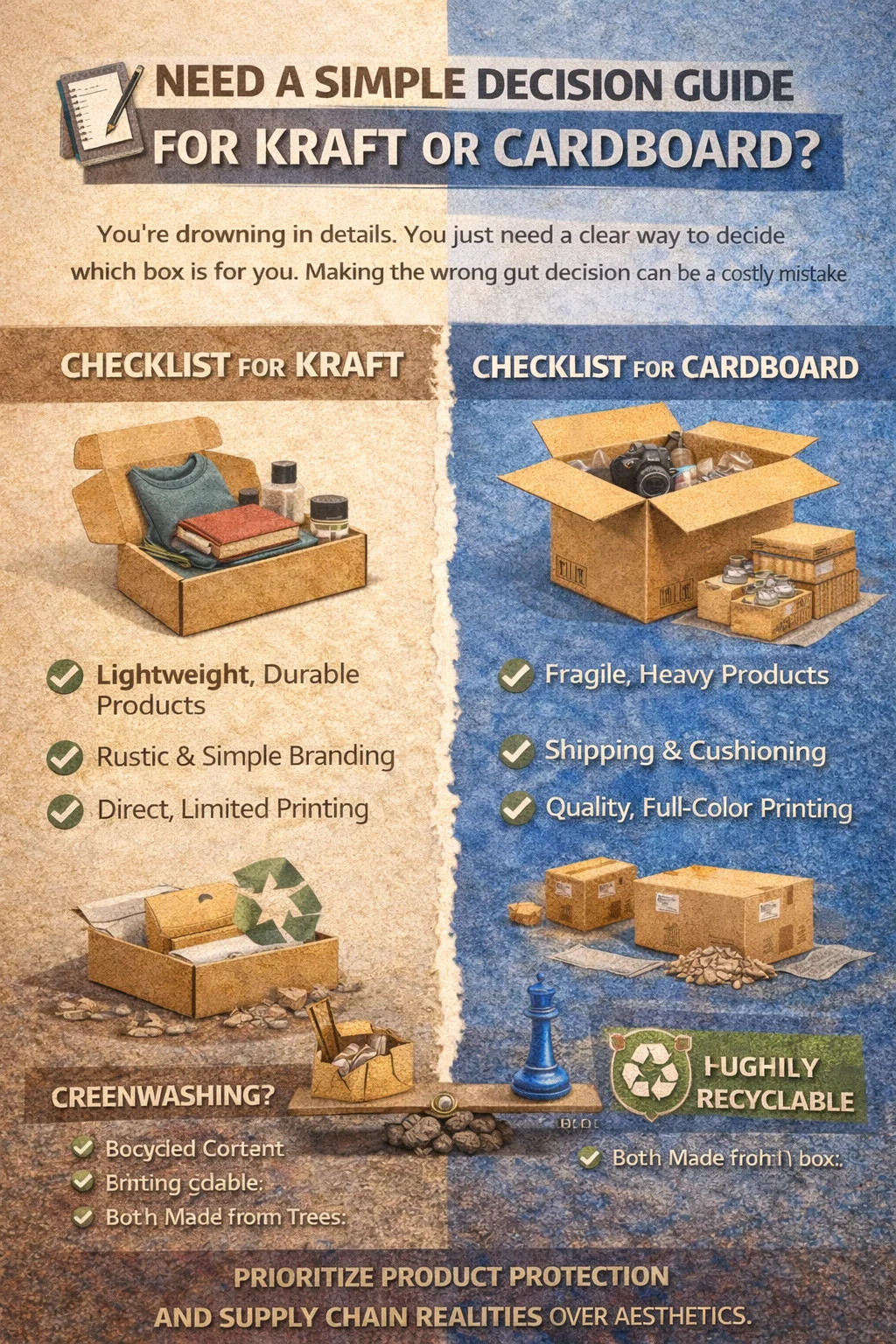

Need a Simple Decision Guide for Kraft or Cardboard?

You're drowning in details. You just need a clear way to decide which box is for you. Making the wrong gut decision can be a costly mistake.

Use this checklist: For lightweight, durable products where branding is rustic, choose Kraft. For fragile, heavy items needing shipping protection and high-end printing, choose corrugated cardboard. Always prioritize product protection and your supply chain needs over pure aesthetics for the best business outcome.

Let's cut through the noise. When I work with clients, I simplify the decision into three questions that focus on performance, not just looks. Answering these will point you in the right direction.

Step 1: Analyze Your Product

Forget about branding for a second and look at the item itself. Is it heavy? Is it fragile? Is it an unusual shape? Does it have sharp corners? The more "yes" answers you have, the more you need the protection of corrugated cardboard.

Step 2: Consider Your Brand and Unboxing

What experience do you want the customer to have? Are you a farm-to-table brand that wants an organic, earthy feel? Kraft is a great fit. Are you a tech company that wants to convey precision and quality? A sleek, litho-laminated corrugated box is a better choice.

Step 3: Talk to Your Supply Chain Partners

This is the step everyone skips. Email your manufacturer and your warehouse or 3PL. Send them the specs of the box you're considering. Ask them, "Do you see any issues with this?" They are the experts in production and logistics. Their feedback is free and invaluable.

| Decision Factor | Choose Kraft if... | Choose Cardboard if... |

|---|---|---|

| Product Weight | Under 1-2 pounds. | Over 1-2 pounds, or is dense. |

| Product Fragility | It's durable (e.g., clothing). | It can break, bend, or scratch easily. |

| Branding Style | You want a natural, rustic, minimal look. | You want a premium, high-end, or protective feel. |

| Shipping Method | It's going inside another box/mailer. | It's being shipped directly by a carrier (UPS, FedEx). |

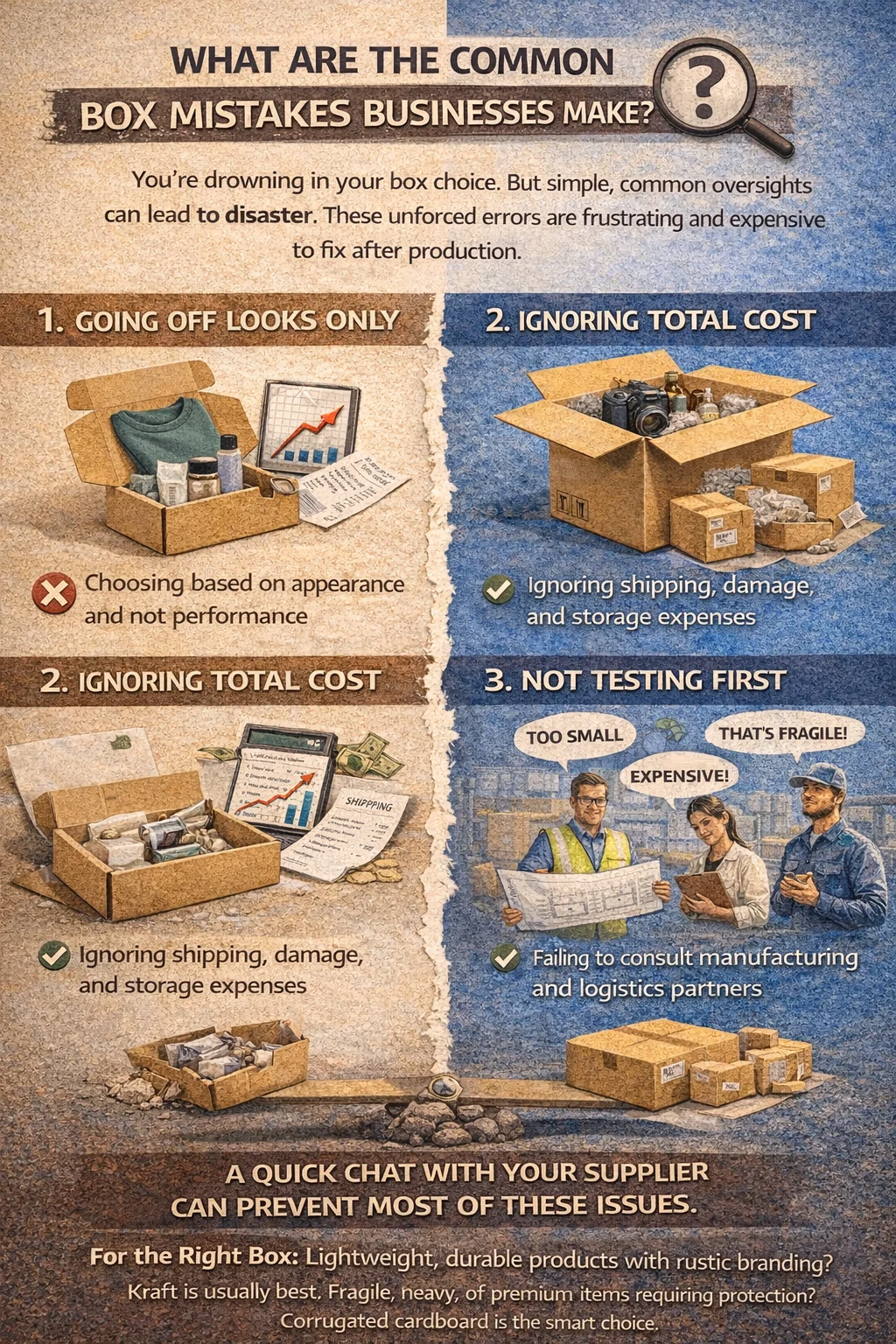

What Are the Common Mistakes Businesses Make?

You're confident in your box choice. But simple, common oversights can lead to disaster. These unforced errors are frustrating and expensive to fix after production.

The biggest mistakes are: choosing a box based on looks alone, ignoring the total cost (shipping, damages), not testing the box with the actual product, and failing to consult with manufacturing and logistics partners. A quick conversation with your supplier can prevent most of these issues.

I've built a career on helping people fix these common, avoidable mistakes. The good news is that they are easy to prevent if you know what to look for.

The "Pinterest" Problem

This is the number one mistake. A founder sees a beautiful image of a product in a box on Pinterest or Instagram and says "I want that." They fall in love with the aesthetic without any thought for the function. But the box in that photo might have been for a photoshoot, not for actual shipping. Or it held a t-shirt, while your product is a glass bottle. Always start with function, then design the aesthetic around it.

Forgetting the Supply Chain

The second mistake is designing the box in a vacuum. You create a perfect unboxing experience but don't consider that the box must be assembled, packed, stacked on a pallet, and thrown in a truck first. The best packaging choice is one that performs consistently from the factory to the customer.

Skipping the Sample Phase

Never, ever place a bulk order without getting a final production sample first. And don't just look at it. Put your product inside, tape it up, and mail it to yourself across the country. See how it arrives. Shake it. Drop it from waist height. This simple, real-world test is the best insurance you can buy.

| Common Mistake | The Consequence | How to Avoid It |

|---|---|---|

| Choosing on Looks | High damage rates, production issues. | Prioritize function (protection) first, then form. |

| Ignoring Total Cost | "Cheap" box costs you more in shipping/damages. | Calculate landed cost per unit, not just unit price. |

| Skipping Tests | Discovering a fatal flaw after ordering 10,000 units. | Always get a final sample and test it in real-world conditions. |

| Not Talking to Partners | Choosing a box that jams machines or can't be stored. | Have a 15-minute call with your factory and 3PL. |

Conclusion

Choosing between kraft and cardboard isn't about looks. It’s about matching the box's strength, cost, and logistics performance to your specific product and business needs for long-term success.

Explore the advantages of kraft packaging for a natural look and lightweight items. ↩

Learn why corrugated cardboard is essential for shipping fragile and heavy items. ↩

Understand the impact of production delays on your business's bottom line. ↩

Understand the relationship between packaging weight and shipping costs. ↩

Find out how proper packaging can prevent damage during shipping. ↩

Discover how the right packaging can enhance your brand image and customer experience. ↩

Understand the importance of packaging in logistics and supply chain management. ↩

Discover how to prevent product damage with the right packaging. ↩

Learn about the long-term effects of customer complaints on your business. ↩

Uncover the hidden costs of packaging that can affect your overall budget. ↩

Get tips on budgeting for packaging to avoid unexpected costs. ↩

Learn how packaging choices can affect customer service efficiency. ↩

Get insights into calculating the true cost of packaging beyond unit price. ↩

Explore the benefits of flexographic printing for kraft packaging. ↩

Discover how litho-lamination can enhance the appearance of corrugated boxes. ↩

Learn about the best packaging solutions for protecting fragile products. ↩